Glass gemstone material dedicated laser marking machine JC-UV-3/5/10

| If you don’t know which model to choose, please contact us directly! |

| We will provide you with the most reasonable solution! |

| Junchuang Laser is now recruiting regional agents, welcome to consult!! |

| Model | JC-UV-3 | JC-UV-5 | |

|---|---|---|---|

| Laser Parameters | 3 5 | 3 5 | 3 5 |

| Wavelength (nm) | 355nm±1nm | 355nm±1nm | 355nm±1nm |

| Average Power (W) | >3W@30kHz | >5W@30kHz | |

| Single Pulse Energy (uJ) | ~100uJ@30kHz | ~160uJ@30kHz | |

| Pulse Width (ns) | ~15ns@30kHz | ~15ns@30kHz | |

| Repetition Rate | 20-500kHz | 20-500kHz | |

| Pulse Stability | <3% rms | <3% rms | <3% rms |

| Long-term Stability | <±3% | <±3% | <±3% |

| Beam Parameters | |||

| Polarization Ratio | Horizontal polarization; >100:1 | Horizontal polarization; >100:1 | Horizontal polarization; >100:1 |

| Beam Diameter | 0.8mm (output aperture) / 5mm (6x beam expander) | 0.8mm (output aperture) / 5mm (6x beam expander) | 0.8mm (output aperture) / 5mm (6x beam expander) |

| Beam Roundness | >90% | >90% | >90% |

| Beam Quality | TEM00, M2 <1.3 | TEM00, M2 <1.3 | TEM00, M2 <1.3 |

| Warm-up Time | <15 minutes at cold start | <15 minutes at cold start | <15 minutes at cold start |

| Power Supply Requirements | DC12V, 350W | DC12V, 350W | |

| Operating Temperature | 10-35℃, humidity <80% | 10-35℃, humidity <80% | 10-35℃, humidity <80% |

| Storage Temperature | -10-40℃, humidity <90% | -10-40℃, humidity <90% | -10-40℃, humidity <90% |

| Cooling Method | Water-cooled | Water-cooled | Water-cooled |

| Operating Water Temperature | 25℃ | 25℃ | 25℃ |

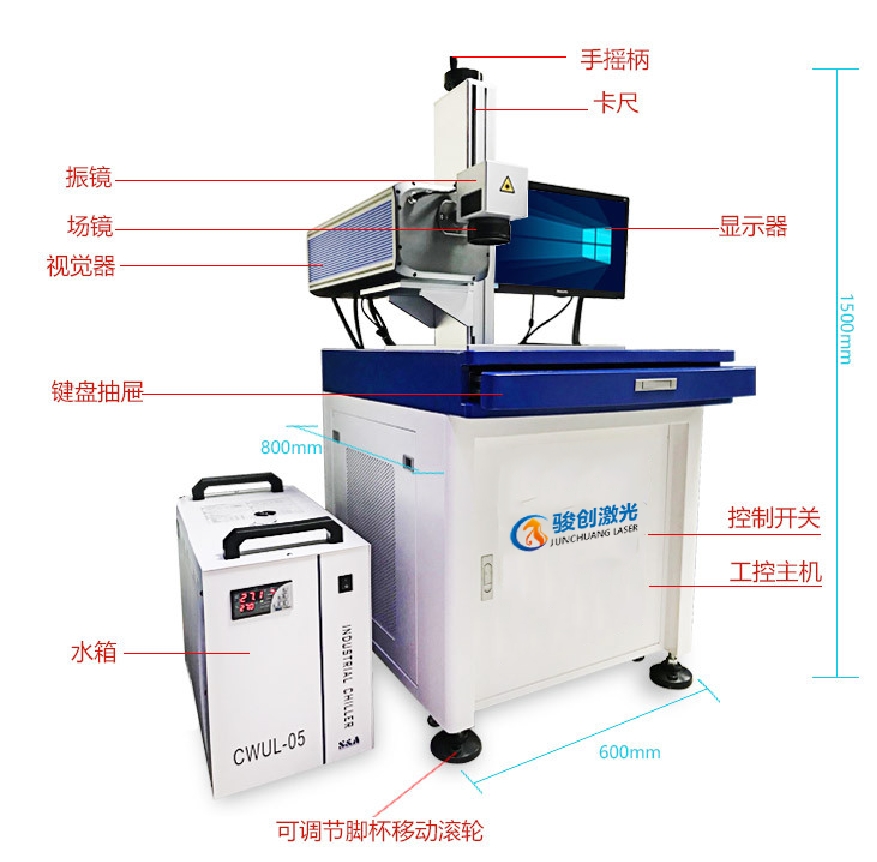

Equipment Introduction:

The JunChuang Laser® UV Laser Marking Machine is developed using a 355nm UV laser. The UV light has an extremely small focused spot, which greatly reduces mechanical deformation of materials and has a small thermal impact during processing. It uses a semiconductor laser pump and undergoes triple frequency doubling within the optical resonant cavity to output a 355nm wavelength laser, with high electro-optic conversion efficiency. The beam quality is TEM00 mode. The accuracy is <5μRad. The maximum speed reaches 1200MM/S.

This equipment uses JunChuang's® exclusively developed laser waveband interception module to intercept and filter out harmonic waves and unstable wavebands in AC and DC power. It inputs and adjusts stable current wavebands to maintain the stability of the laser marking machine. Through JunChuang Laser's® exclusive technology enhancements and adjustments, this equipment offers more stable and durable performance than conventional laser marking machines. JunChuang® industrial laser marking machines are manufactured according to industrial production standards and can operate continuously for 24 hours without interruption. The laser power fluctuation is <2%, power consumption is stable, the laser motion tracking trajectory error is ≤110us, and the repeated positioning accuracy is <5μRad. The operating temperature limit is -5°C to +60°C.

The JunChuang 3W industrial UV laser marking machine is comprised of a JunChuang jointly developed 3W industrial high-energy UV laser, a high-speed scanning galvanometer system, a professional marking control system, marking software, and other components. The laser has advantages such as high efficiency, long lifespan, and maintenance-free operation. This machine is stable in performance, easy to operate, and compact in structure, making it widely applicable for production processing.

Highlights of the JunChuang 3W Industrial UV Laser Marking Machine:

- Functional Characteristics:

- Uses a German semiconductor laser pump, undergoing triple frequency doubling within the optical resonant cavity to output a 355nm wavelength laser with high electro-optic conversion efficiency and TEM00 beam quality.

- The UV laser is a cold light source with a small thermal impact area, and its excellent beam quality creates ultra-high-precision marking effects.

- Uses high-speed digital galvanometer scanning for fast marking speeds, suitable for micro-cutting and drilling (depending on the material).

- No consumables, low operating costs, energy-saving.

- Modular design for easy maintenance and compact size.

- The software can receive DXF, PLT, BMF, AI, JPG, and other formats, and can automatically generate serial numbers, production dates, barcodes, QR codes, and sequential automatic marking. It can cooperate with conveyor belts to achieve online marking.

- User-friendly structural design for convenient system integration and equipment maintenance.

- Powerful user application software with a friendly interface, full functionality, and free upgrades.

- Customized brand parts and excellent global technical support services.

- The software recognizes formats such as ai/pit/dxf/dst/svg/nc/jpc/dot.

- Equipped with laser core optimization technology and waveband interception technology provided by the Singapore Luo Zhengxin PhD team, ensuring stable operation of the machine.

- A new generation of high-speed data processors paired with upgraded genuine or customized control software, enabling precise generation of processing graphic signals and high-speed real-time processing of marking control signals, setting a new standard for high-end industry applications.

Application Fields:

Consumer electronics, mobile phone components, LCD screen engraving of QR codes and logos, ceramics, sapphire wafers, FPC flexible circuit board micro-drilling, cutting biomedical glass scoring, capacitive touchscreen ITO etching.

Suitable Materials:

Metals and various non-metals, ceramics, sapphire wafers, glass, light-transmitting polymers, brittle materials, plastics, etc.

(Note: The table with laser parameters, beam parameters, etc., is repeated in the provided document but not translated again here for brevity.)

JunChuang Galvanometer Laser Head System Technology Introduction:

- The system uses position sensors, error amplifiers, power amplifiers, position discriminators, current integrators, etc., to provide laser operating efficiency.

- Differential photoelectric sensors detect the position of the motor rotor, featuring good linearity, small drift, high resolution, and high repeated positioning accuracy.

- Designed for a load of 10mm mirrors, the motor assembly has high precision, a reasonable structure, small static friction coefficient, and small zero offset, ensuring good dynamic characteristics of the system.

- The driver has position and speed lead detection functions, significantly enhancing the dynamic response efficiency and scanning speed of the entire system.

- Designed with overload, overcurrent, and reverse connection protection to make the system more reliable.

- The entire system adopts electromagnetic compatibility optimization design, featuring high signal-to-noise ratio and strong anti-interference ability.

- Solves common issues such as temperature drift, signal interference, and zero drift of galvanometer motors.

Specifications:

| Specification | Value |

|---|---|

| Positioning Speed | 12000mm/s |

| Writing Speed | 450cps |

| Response Time (1%) | 350us |

| Response Time (10% of Full Stroke) | 750us |

| Tracking Error | ≤110us |

| Accuracy and Error | |

| Linearity | 99.9% |

| Repeated Positioning Accuracy | <5μRad |

| Gain Error | <5mRad |

| Zero Offset (Batch Origin Error) | <5mRad |

| Long-term Drift (Continuous Operation for 8 Hours) | <0.5mRad |

| Proportional Drift | <40PPM/℃ |

| Zero Drift | <15μRad./℃ |

| Laser Input Aperture | 10mm |

Explanation of Galvanometer Principles:

A galvanometer is a special oscillating motor. The principle is that a energized coil generates torque in a magnetic field. Unlike a rotating motor, its rotor applies a restoring torque through the electromagnetic field, proportional to the angle by which the rotor deviates from the equilibrium position. When a current passes through the coil, the rotor deflects to a certain angle where the electromagnetic torque and restoring torque are equal. Therefore, it cannot rotate like an ordinary motor but can only deflect, with the deflection angle proportional to the current.

Control Circuit Principle:

When an input position signal is received, the motor will oscillate to a certain angle according to the conversion ratio between voltage and angle

Model.docx

Page 1

| Material Category | Applicable Materials | Remarks |

|---|---|---|

| Stone | Natural stones (such as granite, marble, slate) | Suitable for surface engraving, high delicacy, suitable for complex patterns and text marking |

| Gemstones (such as jade, emerald, crystal) | Can be used for engraving patterns or text, but power needs to be finely controlled to avoid damage | |

| Synthetic stones (such as artificial marble, quartz stone) | Clear surface marking, suitable for industrial or decorative marking | |

| Glass | Regular float glass | Used for marking patterns, barcodes, QR codes, with clear marking and no additional treatment required |

| Tempered glass | Marking does not affect glass strength, suitable for high-end product packaging or equipment nameplates | |

| Colored glass | Can be used for a variety of surface decorations, with clear marking without damaging the glass's original color | |

| Coated glass (such as low-emissivity glass) | Laser parameters need to be adjusted to ensure that marking does not damage the coating layer | |

| Quartz glass | Fine marking, widely used in high-tech fields such as electronics and medical industries | |

| Acrylic glass (organic glass) | Although it belongs to plastics, it is often classified as glass, suitable for clear and delicate marking |

Model.docx

Page 1

| Material Category | Applicable Materials | Remarks |

|---|---|---|

| Stone | Natural stones (such as granite, marble, slate) | Suitable for surface engraving, high delicacy, suitable for complex patterns and text marking |

| Gemstones (such as jade, emerald, crystal) | Can be used for engraving patterns or text, but power needs to be finely controlled to avoid damage | |

| Synthetic stones (such as artificial marble, quartz stone) | Clear surface marking, suitable for industrial or decorative marking | |

| Glass | Regular float glass | Used for marking patterns, barcodes, QR codes, with clear marking and no additional treatment required |

| Tempered glass | Marking does not affect glass strength, suitable for high-end product packaging or equipment nameplates | |

| Colored glass | Can be used for a variety of surface decorations, with clear marking without damaging the glass's original color | |

| Coated glass (such as low-emissivity glass) | Laser parameters need to be adjusted to ensure that marking does not damage the coating layer | |

| Quartz glass | Fine marking, widely used in high-tech fields such as electronics and medical industries | |

| Acrylic glass (organic glass) | Although it belongs to plastics, it is often classified as glass, suitable for clear and delicate marking |