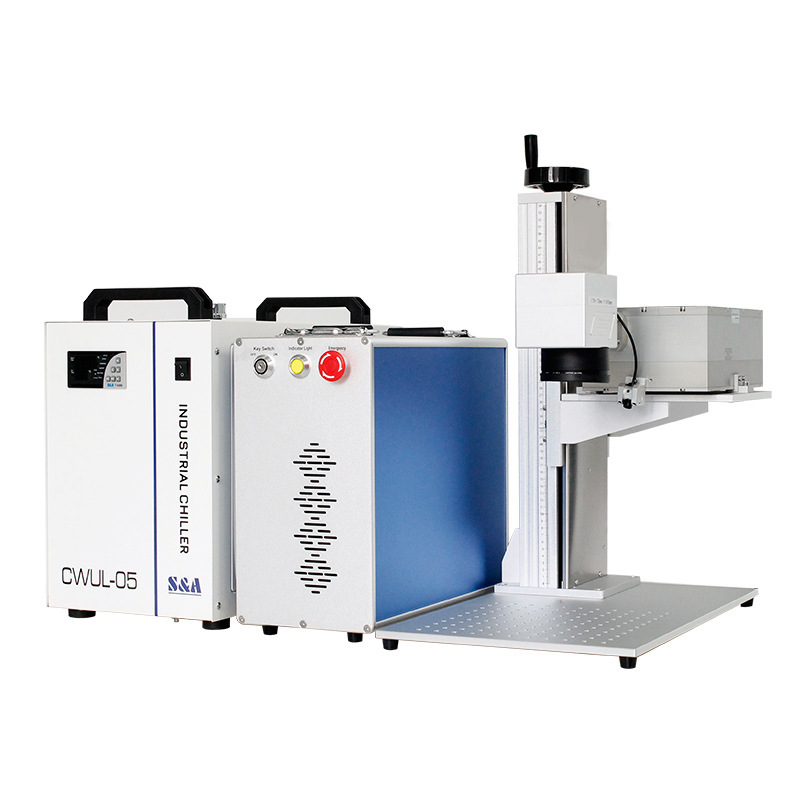

JPT 3W / 5W Water-Cooled UV Laser Marking Machine

| If you don’t know which model to choose, please contact us directly! |

| We will provide you with the most reasonable solution! |

| Junchuang Laser is now recruiting regional agents, welcome to consult!! |

1. Product Overview

The JPT Water-Cooled UV Laser Marking Machine is equipped with a high-performance 355nm UV laser source from JPT (Shenzhen JPT Optoelectronics Co., Ltd.).

Designed for high-precision, low-heat, and fine-detail marking, this machine is ideal for heat-sensitive materials or components that require micro-scale engraving.

Featuring an integrated water-cooling system, the machine provides superior thermal stability, allowing long-duration, high-intensity operation in industrial environments. It is widely used in electronics, plastics, glass, ceramics, wafers, medical devices, and packaging industries.

2. Key Features

High-Performance JPT UV Laser

Equipped with a 3W or 5W 355nm UV laser, capable of ultra-fine marking.

Cold-light processing ensures minimal heat-affected zones, avoiding burns or deformation.

Stable output with high beam quality guarantees consistent, precise marking.

Water-Cooled Design – High Stability

Integrated water-cooling system maintains optimal laser temperature for continuous high-power operation.

Ideal for long-duration industrial use or high-duty production lines.

Ensures consistent performance and extended laser lifespan compared to air-cooled systems.

Intelligent Control System

Comes with EZCAD software, supporting both English and Chinese interfaces.

Compatible with various formats: PLT, BMP, DXF, AI, JPG, PNG, etc.

Supports text, logos, QR codes, barcodes, serial numbers, automatic date, and batch coding.

Can be integrated into production lines for flying (online) marking.

Wide Material Compatibility

Plastics: ABS, PVC, PE, PBT, PC, silicone, nylon, etc.

Metals: Stainless steel, aluminum, copper, titanium (surface marking).

Other Materials: Glass, ceramics, wafers, silicon, sapphire, PCB, films.

Water-cooling ensures precise marking even under high-speed or extended operations.

Compact & Reliable Design

Industrial aluminum frame for durability and stability.

High-precision galvanometer system for fast and accurate marking.

Imported focusing lens ensures uniform marking quality.

Water-cooled system maintains laser stability under heavy-duty operation.

3. Technical Specifications

| Item | Specification |

|---|---|

| Laser Brand | JPT |

| Laser Type | UV Laser |

| Output Power | 3W / 5W |

| Wavelength | 355 nm |

| Beam Quality (M²) | < 1.2 |

| Marking Area | 110×110mm (Optional: 150×150mm) |

| Marking Speed | ≤ 7000 mm/s |

| Minimum Line Width | 0.01 mm |

| Minimum Character | 0.15 mm |

| Cooling Method | Water-Cooled |

| Control Software | EZCAD (English/Chinese) |

| Supported Formats | PLT, BMP, DXF, AI, JPG, PNG, TTF |

| Power Supply | AC 110V / 220V ±10%, 50/60Hz |

| Working Environment | 0–35°C, Humidity < 80% |

| Laser Lifetime | ≥20,000 hours |

4. Product Advantages

Cold-light marking avoids heat damage or material deformation

Ultra-fine and high-contrast engraving

Water-cooling ensures stability under continuous high-power operation

Suitable for glass, plastics, ceramics, wafers, and other precision materials

OEM/ODM customization available for industrial applications

5. Optional Configurations

Electric or motorized lifting column / precision work platform

Flying (online) marking system for production lines

3D dynamic focusing module for curved surface marking

Safety enclosure and fume extraction system

CCD camera positioning system

6. Typical Applications

Mobile phone buttons and plastic shell marking

Medical device serial numbers and anti-counterfeit codes

Glass bottles and transparent packaging engraving

FPC / PCB circuit board micro-marking

Food and cosmetic packaging batch coding