What laser marking machine is used for glass, stone and ceramics

| If you don’t know which model to choose, please contact us directly! |

| We will provide you with the most reasonable solution! |

| Junchuang Laser is now recruiting regional agents, welcome to consult!! |

For glass, stone, wood, and ceramics, choosing the appropriate laser marking machine depends on the characteristics of the materials and the processing requirements. Below is a detailed analysis and recommendation for each material:

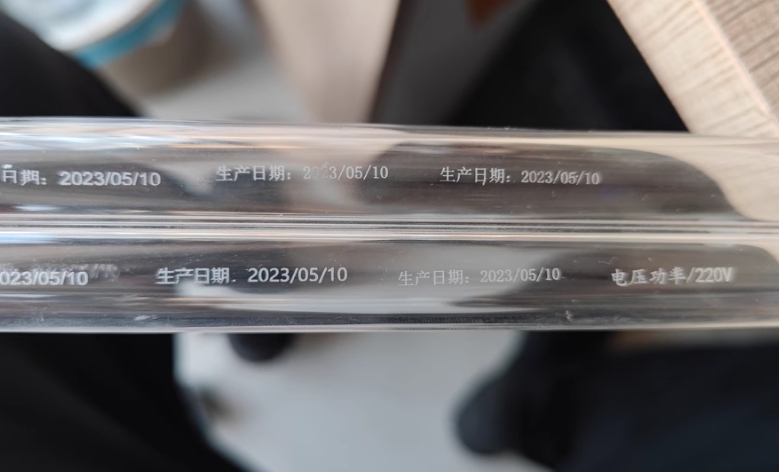

1. Glass

Recommended Laser Marking Machine: UV Laser Marking Machine or Ultrafast (Femtosecond) Laser Marking Machine

- UV Laser Marking Machine:

- Wavelength of 355nm, with concentrated energy and minimal heat-affected zones.

- Suitable for precise markings on glass surfaces, such as QR codes, text, or patterns.

- Does not cause cracks or thermal damage, ideal for high-precision applications.

- Ultrafast (Femtosecond) Laser Marking Machine:

- Extremely short pulse width (femtosecond level), with highly concentrated energy.

- Can achieve higher-quality internal engraving effects (e.g., 3D internal engraving).

- Suitable for high-end applications like smartphone screens or optical lenses.

2. Stone

Recommended Laser Marking Machine: CO2 Laser Marking Machine

- CO2 Laser Marking Machine:

- Wavelength of 10.64μm, with good absorption by stone surfaces.

- Suitable for engraving or marking on stone surfaces, such as text, patterns, or logos.

- High processing efficiency and low cost.

- Note: Stones are hard materials, so laser power and frequency need to be adjusted for optimal results.

3. Wood

Recommended Laser Marking Machine: CO2 Laser Marking Machine

- CO2 Laser Marking Machine:

- Wavelength of 10.64μm, perfectly suited for wood's absorption characteristics.

- Can achieve varying depths of engraving effects on wood surfaces for art pieces, labels, or decorative items.

- Fast processing speed, suitable for mass production.

- Note: Wood is flammable, so laser power must be controlled to avoid excessive carbonization or burning.

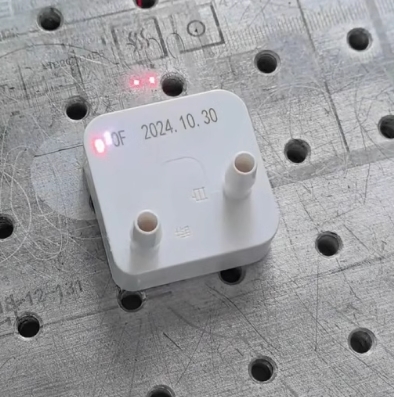

4. Ceramics

Recommended Laser Marking Machine: UV Laser Marking Machine or Fiber Laser Marking Machine (for specially coated ceramics)

- UV Laser Marking Machine:

- No thermal damage to ceramic surfaces, suitable for fine markings.

- Commonly used for electronic component housings, tableware, or other precision ceramic products.

- Fiber Laser Marking Machine (for specially coated ceramics):

- If the ceramic surface has a metallic coating or special treatment, fiber laser marking machines can also achieve good results.

- Clear and durable markings, suitable for industrial applications.

Summary Table

| Material Category | Recommended Laser Marking Machine | Features and Applicable Scenarios |

|---|---|---|

| Glass | UV Laser Marking Machine<br>Femtosecond Laser Marking Machine | High-precision marking, no cracks or thermal damage; suitable for QR codes, text, patterns, or 3D internal engraving. |

| Stone | CO2 Laser Marking Machine | Low cost, high efficiency; suitable for engraving text, patterns, or logos. |

| Wood | CO2 Laser Marking Machine | Fast and efficient, suitable for artistic carving, labeling, or decorative item production; avoid excessive charring. |

| Ceramics | UV Laser Marking Machine<br>Fiber Laser Marking Machine | UV lasers are suitable for fine marking, fiber lasers are suitable for specially coated ceramics; widely used in electronics, tableware, etc. |

Notes

- Test Samples: The actual performance of different materials may vary due to differences in composition. It is recommended to bring real samples to professional manufacturers for testing.

- Processing Parameters: Adjust laser power, frequency, and speed based on material thickness, hardness, and surface characteristics for optimal results.

- Equipment Cost: UV lasers and femtosecond lasers have higher equipment costs and are suitable for high-precision needs, while CO2 lasers have lower costs and are suitable for regular processing.

I hope this information helps! If you have any other questions, feel free to ask.

What laser marking machine is used for glass, stone and ceramics Marking material examples.(Only some cases are shown.)

Leave Your Message

Write your message here and send it to us