What laser marking machine is used for non-metallic materials

| If you don’t know which model to choose, please contact us directly! |

| We will provide you with the most reasonable solution! |

| Junchuang Laser is now recruiting regional agents, welcome to consult!! |

Non-metal materials are typically marked using CO2 laser marking machines or UV laser marking machines, as these devices offer better adaptability and processing effects for non-metal materials. Below is a guide on which laser marking machines are suitable for different non-metal materials:

1. CO2 Laser Marking Machine

Suitable Materials:

- Bamboo and Wood Products: Such as bamboo sheets, wooden boards.

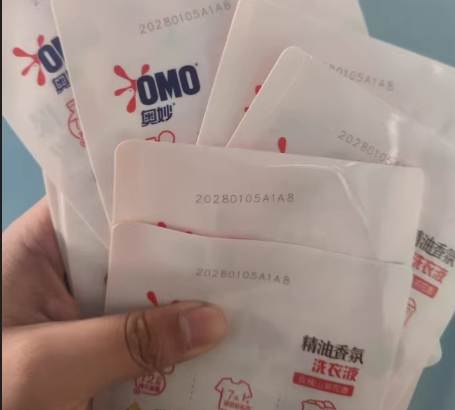

- Plastic Products: Such as ABS, PP, PVC, and other common plastics.

- Acrylic (Organic Glass): Ideal for engraving and cutting.

- Leather: Used to create intricate patterns or text.

- Paper and Fabric: Suitable for packaging, labels, and the clothing industry.

- Epoxy Resin: Widely used in electronic component encapsulation.

- Rubber: Such as gaskets, tire surface markings.

Features:

- Wavelength of 10.64μm, in the mid-infrared band, suitable for non-metal absorption.

- High power output, capable of achieving deep engraving or cutting.

- Broad application range with relatively low cost.

2. UV Laser Marking Machine

Suitable Materials:

- Plastics: Especially heat-sensitive plastics (such as PC, PMMA).

- Glass: Suitable for precision processing, such as smartphone screens or optical lenses.

- Ceramics: Ideal for fine markings, such as electronic component housings.

- Film Materials: Such as PET film, PE film.

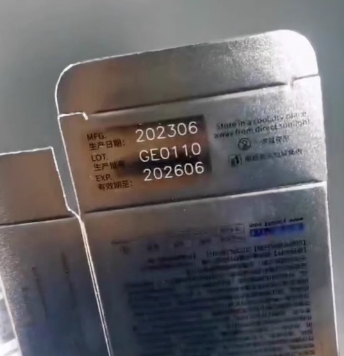

- Pharmaceutical Packaging: Such as medicine bottles, medicine boxes with QR codes or batch numbers.

Features:

- Uses ultraviolet wavelengths (approximately 355nm), with concentrated energy and minimal heat-affected zones.

- Friendly to heat-sensitive materials, avoiding deformation or damage.

- High marking precision, suitable for small parts or applications requiring high accuracy.

3. Fiber Laser Marking Machine (Special Cases)

Although fiber laser marking machines are primarily used for metal materials, they can occasionally be used for non-metal materials under specific conditions, such as:

- Plastics: Some specially modified plastics can be marked by adjusting parameters.

- Coated Materials: Such as non-metal substrates with metallic coatings.

Notes:

- The wavelength of fiber lasers (about 1064nm) has low absorption for most non-metal materials, so the results may not be as ideal as with CO2 or UV lasers.

- Not recommended for flammable or heat-sensitive materials.

How to Choose the Right Laser Marking Machine?

| Material Category | Recommended Laser Marking Machine | Reason |

|---|---|---|

| Bamboo/Wood, Acrylic | CO2 Laser Marking Machine | High absorption rate, good processing efficiency, low cost. |

| Plastics | CO2 or UV Laser Marking Machine | Depends on the type of plastic; heat-sensitive plastics prefer UV lasers. |

| Glass, Ceramics | UV Laser Marking Machine | High precision, minimal heat effect, suitable for fragile or fine materials. |

| Paper, Fabric | CO2 Laser Marking Machine | Low cost, clear results, suitable for large-area processing. |

| Pharmaceutical Packaging | UV Laser Marking Machine | Non-contact processing, environmentally friendly, and suitable for high-precision requirements. |

Summary

- CO2 Laser Marking Machines are the preferred choice for marking non-metal materials, especially bamboo/wood, plastics, leather, etc.

- UV Laser Marking Machines are more suitable for heat-sensitive or high-precision processing materials, such as glass, ceramics, films, etc.

- If you are unsure whether a particular material is suitable for a certain laser marking machine, it is recommended to bring a sample to the Junchuang Laser manufacturer for testing to ensure the best results.

What laser marking machine is used for non-metallic materials Marking material examples.(Only some cases are shown.)

Leave Your Message

Write your message here and send it to us