Laser marking machine application solutions for metal materials

| If you don’t know which model to choose, please contact us directly! |

| We will provide you with the most reasonable solution! |

| Junchuang Laser is now recruiting regional agents, welcome to consult!! |

When it comes to laser marking on metal materials, the following types of laser marking machines can be chosen:

Fiber Laser Marking Machine:

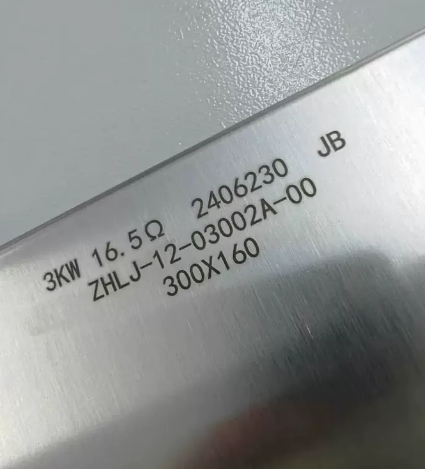

- Principle and Characteristics: It utilizes a fiber laser to output high-energy laser beams, which are focused on the workpiece surface through lenses to achieve high-precision marking.

- Beam Quality: Excellent beam quality with an output central wavelength of 1064nm and high electro-optic conversion efficiency.

- Material Applicability: Suitable for metal materials and some non-metal materials, such as stainless steel, aluminum alloy, plastic, ceramic, etc.

- Application Advantages:

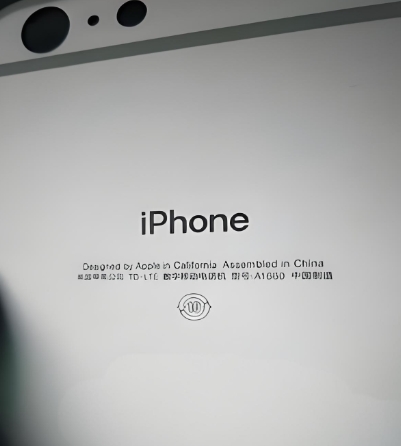

- High Precision: Ideal for products requiring high marking accuracy and fine pattern detail, such as ICs, mobile phone cases, buttons, etc.

- Long Lifespan: The machine has a long lifespan, low failure rate, and stable performance.

- Energy-saving and Environmentally Friendly: Air-cooled, with low operating costs.

- Flexibility: Capable of engraving on metals and some non-metal materials, especially suitable for applications requiring high depth, smoothness, and precision.

Ultraviolet Laser Marking Machine:

- Principle and Characteristics: Equipped with a deep ultraviolet laser, it produces an extremely small focused spot with minimal heat-affected zone.

- Material Applicability: Suitable for metals and a variety of non-metal materials, such as plastic, glass, jewelry, etc.

- Application Advantages:

- Ultra-fine Marking: Capable of producing clear and precise marks on materials, advantageous for materials with poor heat resistance.

- High Precision: High positioning accuracy and efficient operation.

- Pollution-free: Uses cold light or UV laser technology, with no heat affect, avoiding damage to the material surface.

YAG Laser Marking Machine:

- Principle and Characteristics: Uses a YAG crystal as the working medium, generating a laser beam through electro-optic Q-switching technology.

- Material Applicability: Commonly used for fine marking on metal materials.

- Application Advantages:

- High Precision: Suitable for applications requiring high marking accuracy.

- Good Stability: Stable performance, suitable for long-term continuous operation.

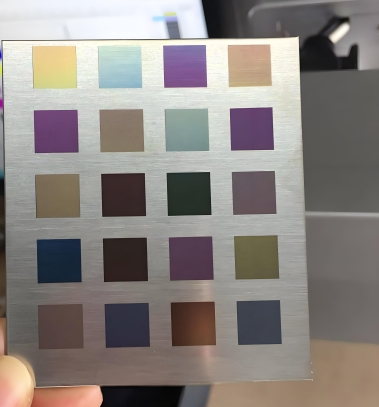

MOPA Laser Marking Machine:

- Principle and Characteristics: By adjusting the pulse width and frequency, it achieves flexible marking effects.

- Material Applicability: Suitable for marking on metal and non-metal materials.

- Application Advantages:

- High Flexibility: Easily achieves different colors and depths of marks.

- High Precision: Suitable for applications requiring high marking quality.

Summary:

For laser marking on metal materials, the fiber laser marking machine is currently the most widely used model on the market. With its high efficiency and versatility, it can meet the fine marking needs of metal materials. The ultraviolet laser marking machine also has unique advantages in ultra-fine marking on metal materials. In addition, the YAG laser marking machine and the MOPA laser marking machine are also suitable for marking on metal materials and can be chosen based on specific needs.

When selecting a laser marking machine, in addition to considering material applicability, attention should also be paid to factors such as equipment performance parameters (e.g., laser power, marking speed, marking depth, etc.), brand reputation, and after-sales service to ensure the selection of equipment that meets one's own needs.

Here is a table of common metal materials that can be processed by a fiber laser marking machine:

| No. | Metal Category | Specific Materials | Applicability Notes |

|---|---|---|---|

| 1 | Iron and Steel | Carbon steel, Stainless steel, Galvanized steel | Fiber laser marking provides clear results for text, patterns, or QR codes. |

| 2 | Aluminum and Alloys | Industrial pure aluminum, Aluminum alloys (e.g., 6061, 7075) | Marked surfaces remain smooth, often used for electronic device housings and parts identification. |

| 3 | Copper and Alloys | Pure copper, Brass | Although copper has lower laser absorption, good results can still be achieved by adjusting parameters. |

| 4 | Titanium and Alloys | Commercial pure titanium, Titanium alloys (e.g., Ti-6Al-4V) | Widely used in aerospace and medical device fields. |

| 5 | Magnesium and Alloys | AZ31, AZ91 | Suitable for permanent markings on lightweight parts. |

| 6 | Zinc and Alloys | Die-cast zinc alloy | Commonly used for markings on small parts and decorative items. |

| 7 | Cobalt-Chromium Alloys | Cobalt-chromium-molybdenum alloy | Mainly used for marking medical implants and dental instruments. |

| 8 | Precious Metals | Gold, Silver, Platinum | Fine marking can be achieved, widely used in the jewelry industry. |

Notes:

- The applicability of fiber laser marking machines may vary depending on material properties and equipment parameters.

- For highly reflective metals (such as copper and aluminum), laser power and frequency may need to be optimized to achieve ideal results.

- Special alloys or coated materials may require testing to confirm optimal parameters.