Differences Between Flying Laser Marking Machines and Laser Coding Machines

Differences Between Flying Laser Marking Machines and Laser Coding Machines

Flying laser marking machines and laser coding machines are both used for industrial marking, but they differ significantly in terms of operating principles, application scenarios, and performance characteristics. Below is a detailed comparison to help you understand their distinctions and respective advantages.

1. Definition and Working Principles

Flying Laser Marking Machine:

This device uses a high-energy laser beam to create permanent marks on the surface of a workpiece. The marking process involves heating or vaporizing the material's surface to form durable marks.- Working Principle: The laser beam scans dynamically via galvanometers to achieve precise marking of text, patterns, or QR codes, even on fast-moving objects in production lines.

Laser Coding Machine:

Laser coding machines are specialized for high-speed dynamic marking, typically used to print production dates, batch numbers, and simple barcodes. Compared to flying laser marking machines, they perform shallow marking, making them suitable for light marking needs.Working Principle: The laser beam evaporates or discolors the surface of the material to form characters and symbols. It operates quickly but with less depth compared to laser marking.

2. Marking Effects

Flying Laser Marking Machine:

- Marking Depth: Capable of deep engraving, suitable for high-precision and durable marking applications, such as metal components.

- Marking Content: Supports complex designs, including patterns, QR codes, and logos, with high clarity and precision.

- Marking Durability: Produces permanent marks that are wear-resistant, corrosion-proof, and fade-resistant.

Laser Coding Machine:

- Marking Depth: Produces shallow marks, primarily for surface-level information like text and codes.

- Marking Content: Suitable for simple content like dates, batch numbers, and barcodes with moderate precision.

Marking Durability: While reasonably durable, it is not as robust as the deep marks created by laser marking machines.

3. Speed and Efficiency

Flying Laser Marking Machine:

- Suitable for medium to high-speed production lines, maintaining excellent quality even for complex patterns.

- May require additional setup time for high-precision tasks.

Laser Coding Machine:

- Designed for ultra-fast marking, ideal for rapid production environments such as bottle caps and food packaging.

- Faster than flying laser marking machines but with lower precision.

4. Application Scenarios

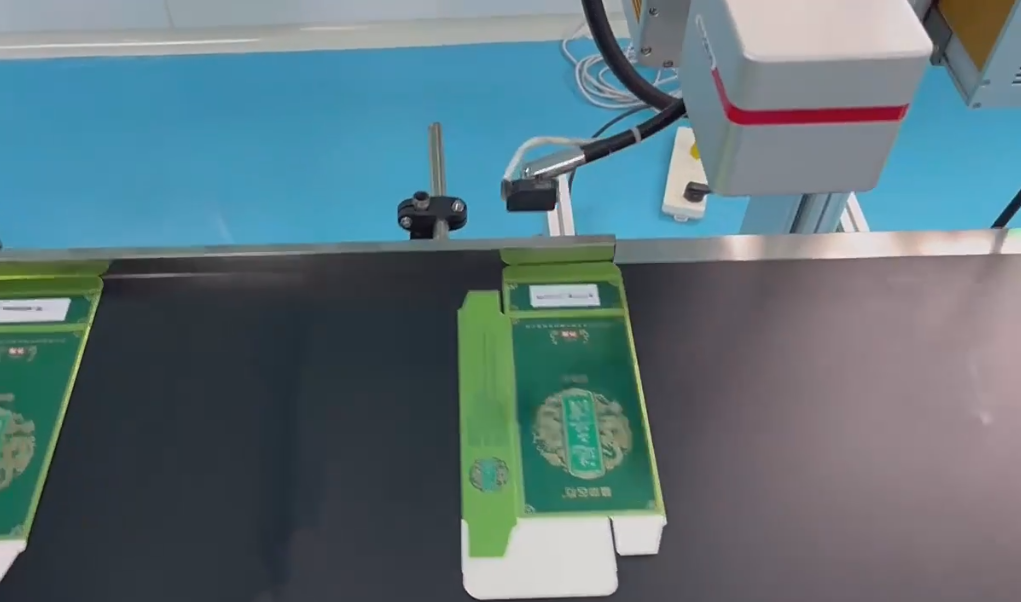

Flying Laser Marking Machine:

- Complex Applications: Ideal for high-precision or intricate designs such as QR codes, logos, and deep engraving.

- High-Value Products: Suitable for products requiring durable and brand-enhancing marks, such as automotive parts and electronic components.

- Material Versatility: Compatible with a wide range of materials, including metals, plastics, glass, and wood.

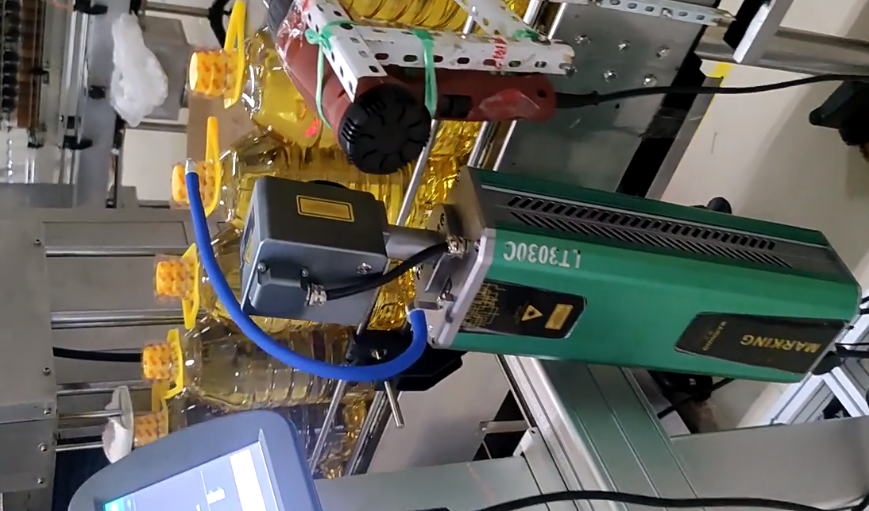

Laser Coding Machine:

- Fast Marking: Perfect for printing dates and batch numbers in industries like food and beverage.

- Consumable Products: Commonly used for simple marking on disposable packaging such as paper or plastic film.

5. Cost and Maintenance

Flying Laser Marking Machine:

- Higher initial cost, especially for models with high precision and advanced features.

- Low operational and maintenance costs since it does not require consumables, making it economical in the long run.

Laser Coding Machine:

- Lower initial cost, making it suitable for high-volume, simple marking applications.

- While it does not use consumables like ink, its application range may be limited due to the shallow marking depth.

6. Typical Applications Comparison

| Machine Type | Industries | Typical Applications |

|---|---|---|

| Flying Laser Marking Machine | Automotive, Electronics, Pharmaceuticals, Consumer Goods | QR codes, deep engraving of logos, high-precision designs |

| Laser Coding Machine | Food, Beverage, Packaging | Date codes, batch numbers, simple barcodes on packaging |

7. Choosing the Right Machine

Flying Laser Marking Machine:

Ideal for applications requiring high precision, deep marking, or complex content like logos and QR codes. It is perfect for enhancing brand value and creating durable marks.Laser Coding Machine:

Best suited for high-speed production lines requiring simple markings like production dates and batch numbers. It excels in scenarios where speed is more critical than precision.

Flying laser marking machines and laser coding machines each have their strengths. The former focuses on precision and marking quality, making it suitable for high-value products and complex applications. The latter emphasizes speed and efficiency, making it ideal for fast-moving production lines with simpler marking needs. Choosing the right machine based on your production requirements and budget will significantly enhance productivity and product quality.

laser marking machine for meta

laser marking machine for meta

laser marking machine price in

laser marking machine price in

HS code information of laser m

HS code information of laser m

20w fiber laser marking machin

20w fiber laser marking machin