Applications of Flying Laser Marking Machines

Flying laser marking machines are advanced inline marking systems designed to achieve high-speed, high-efficiency, and non-contact laser marking in continuous production environments. These machines are particularly suitable for scenarios requiring mass marking, such as assembly lines or automated production settings. Below is an overview of the key functionalities and applications of flying laser marking machines.

1. Main Functions of Flying Laser Marking Machines

Dynamic Marking:

Flying laser marking machines use dynamic laser marking technology to achieve precise marking on moving objects. This makes them ideal for assembly line production, enabling large-scale marking tasks in a short time.

Non-Contact Processing:

The marking process uses a laser beam to mark materials without physical contact, preventing damage to the workpiece. This method is compatible with various materials such as metals, plastics, and glass.Permanent Marking:

Laser marking produces durable marks that resist wear, corrosion, and fading, ensuring high-quality, long-lasting results.High-Speed and High-Efficiency:

Flying laser marking machines can mark items on high-speed production lines without halting operations, significantly improving productivity.Support for Various Content Formats:

These machines can mark text, graphics, QR codes, barcodes, serial numbers, and date information, offering flexible customization options.Wide Material Compatibility:

They can process diverse materials, including metals (stainless steel, aluminum alloys), non-metals (plastics, wood, glass), coated surfaces, and electronic components.

2. Applications of Flying Laser Marking Machines

Food and Beverage Industry:

- Mark production dates, batch numbers, and expiration dates on food packaging.

- Dynamic marking on bottle caps or containers, including barcodes and QR codes.

Electronics and Electrical Appliances:

Mark serial numbers, model information, and brand logos on circuit boards, electronic components, and casings.

- Anti-counterfeiting marks on home appliance surfaces to enhance brand value.

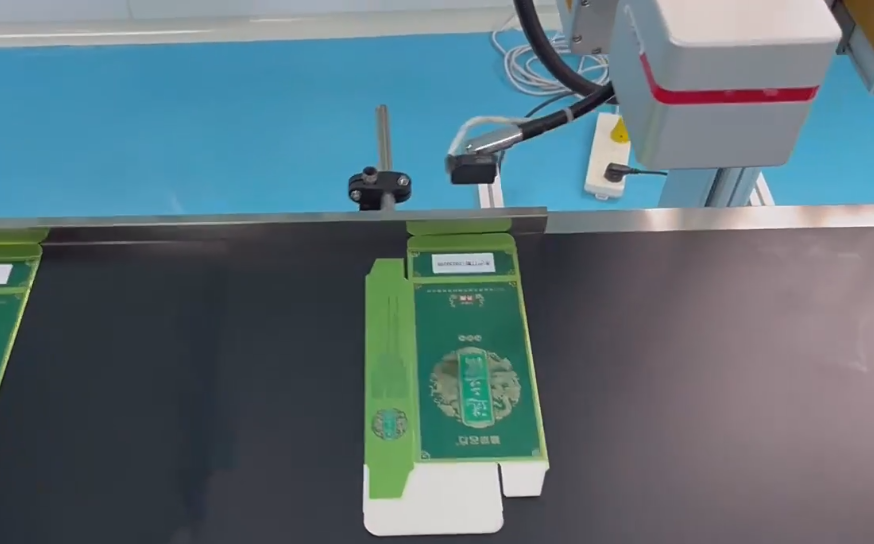

Pharmaceutical Industry:

- Mark production batch numbers, expiration dates, and QR codes on medicine packaging.

- Ensure traceability of pharmaceuticals to meet regulatory requirements.

Automotive Manufacturing Industry:

- Mark part numbers and QR codes on automotive components (e.g., engines, brake discs, bearings).

- Brand or functional labels on plastic or metal parts.

Consumer Goods Industry:

- Mark logos, QR codes, and anti-counterfeiting information on cosmetic bottles and detergent packaging.

- Create unique patterns or text on glassware or ceramic products.

Cable and Pipe Industry:

- Mark specifications, lengths, and production batch information on cable surfaces.

- Dynamic marking on pipes to enhance product information management.

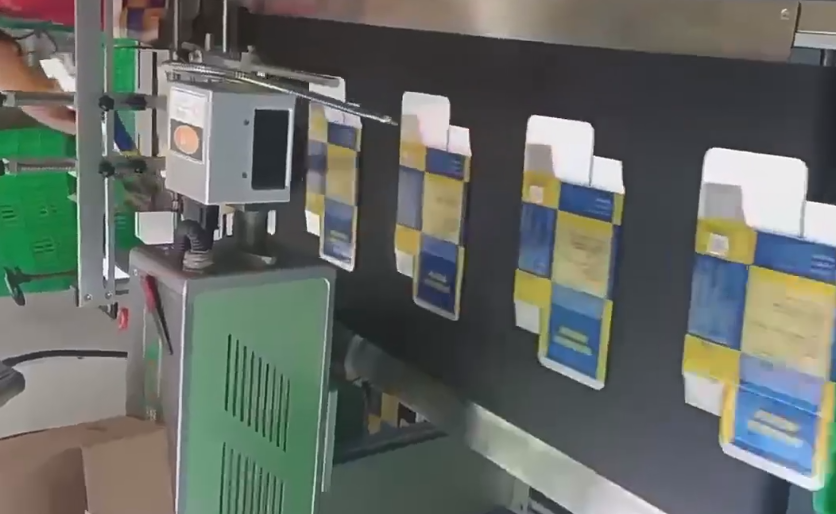

Packaging and Labeling Industry:

- Mark QR codes, barcodes, and logos on cartons, plastic bags, and labels.

Achieve rapid, large-scale marking for high-speed production lines.

3. Advantages of Flying Laser Marking Machines

High Adaptability:

Compatible with various types of production lines, from high-speed assembly lines to complex automated equipment.Environmentally Friendly:

The laser marking process produces no chemical waste, making it an eco-friendly solution.Reduced Production Costs:

Unlike traditional marking methods (e.g., inkjet printing), laser marking requires no consumables, significantly lowering long-term operational costs.Enhanced Product Quality:

Laser markings are precise, clear, and durable, resistant to abrasion or environmental conditions, and enhance product quality.

4. Future Prospects

With the advancement of industrial automation and smart manufacturing, the applications of flying laser marking machines will expand further, including:

- Implementing full traceability in smart factories through precise product marking.

- Integrating with IoT technology to assign digital identities (e.g., smart QR codes) to products.

- Addressing marking needs for emerging materials (e.g., flexible displays, composite materials).

Flying laser marking machines excel in dynamic, high-speed, and high-precision marking, making them indispensable tools on modern production lines. Widely used across multiple industries, these machines provide efficient, eco-friendly, and cost-effective marking solutions, while also enhancing product quality and brand value.

laser marking machine for meta

laser marking machine for meta

laser marking machine price in

laser marking machine price in

HS code information of laser m

HS code information of laser m

20w fiber laser marking machin

20w fiber laser marking machin