How to Adjust the Speed of a Laser Marking Machine

Adjusting the speed of a laser marking machine is a key step to optimizing processing efficiency and marking quality. Speed settings directly affect the laser's dwell time on the material surface, determining the marking depth, clarity, and efficiency. Below is a detailed guide on how to adjust the speed of a laser marking machine.

1. Methods to Adjust Speed

Set Speed via Marking Software:

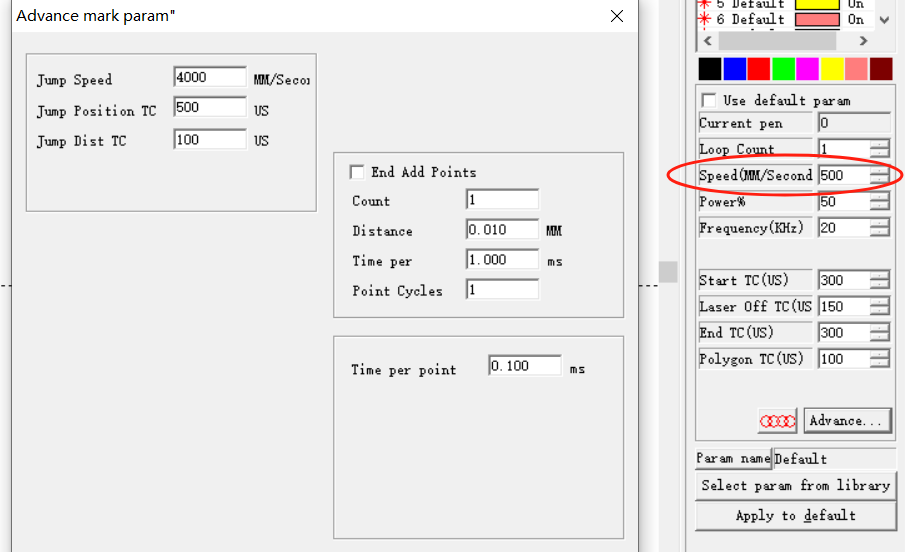

The speed of a laser marking machine is typically adjusted through the accompanying software (e.g., EzCad, LaserCAD). Steps include:- Open the marking software.

- Locate the "Speed" option in the parameter settings interface (usually in the marking parameters window).

- Input the desired speed value (measured in mm/s).

Save the parameter settings and perform a test mark.

select the Appropriate Speed Range:

Choose a suitable speed range based on the material and marking requirements. Generally, speed ranges from 0-2000mm/s, and the specific value should be adjusted considering the following:- Deep Engraving: Use lower speeds (e.g., 200-400mm/s).

- Shallow or Quick Marking: Use higher speeds (e.g., 500-1000mm/s).

Coordinate with Other Parameters:

Laser power, frequency, and speed need to be balanced. When adjusting speed, also modify other parameters to achieve the best results.

2. Key Factors Affecting Speed Adjustment

Material Characteristics:

Different materials require different speed settings:- Metal Materials: Lower speeds (for deeper markings and longer laser exposure).

- Non-Metal Materials (e.g., plastic, wood): Higher speeds to prevent overheating or deformation.

Marking Content:

- Intricate patterns or fine text require reduced speed to ensure clarity.

- Simple patterns or large-area filling can use higher speeds to save time.

Laser Power and Frequency:

- Higher laser power allows for increased speed to avoid overheating.

- When using a higher frequency, the speed should also be increased to prevent excessive overlapping of laser pulses.

3. Common Issues and Solutions with Speed Adjustment

Issue: Faint or Unclear Markings

Cause: Speed is too high, resulting in insufficient laser dwell time.

Solution: Reduce the speed and increase the power and frequency as needed.Issue: Material is Scorched or Melted

Cause: Speed is too low, causing excessive laser exposure.

Solution: Increase the speed and decrease the power and frequency.Issue: Blurry Edges or Distorted Patterns

Cause: Misaligned galvo system or improper speed settings.

Solution: Calibrate the galvo system and ensure speed aligns with the scanning area.

4. Recommended Speed Settings

Below are suggested speed values for common materials (actual values may vary depending on equipment and material):

| Material Type | Speed (mm/s) | Recommended Parameter Settings |

|---|---|---|

| Stainless Steel | 200-400 | Power: 70%-90%, Frequency: 30-60kHz |

| Aluminum Alloy | 300-500 | Power: 60%-80%, Frequency: 20-50kHz |

| Plastic (ABS) | 400-800 | Power: 30%-50%, Frequency: 10-30kHz |

| Wood | 300-600 | Power: 50%-80%, Frequency: 10-20kHz |

| Glass | 200-300 | Power: 50%-70%, Frequency: 20-40kHz |

5. Testing and Optimization

To identify the optimal speed setting, follow these steps:

- select a representative material sample.

- Start with a moderate speed (e.g., 500mm/s) and gradually adjust it while observing the results.

- Determine the best speed based on the marking depth, clarity, and material surface condition.

- Record the optimal parameters for each material to facilitate future operations.

Adjusting the speed of a laser marking machine requires careful consideration of material properties, marking content, laser power, and frequency. By fine-tuning the parameters, you can achieve efficient and clear marking results. It is recommended to test settings and save successful configurations to ensure consistent production efficiency and marking quality.

laser marking machine for meta

laser marking machine for meta

laser marking machine price in

laser marking machine price in

HS code information of laser m

HS code information of laser m

20w fiber laser marking machin

20w fiber laser marking machin