UMC4 laser marking software download

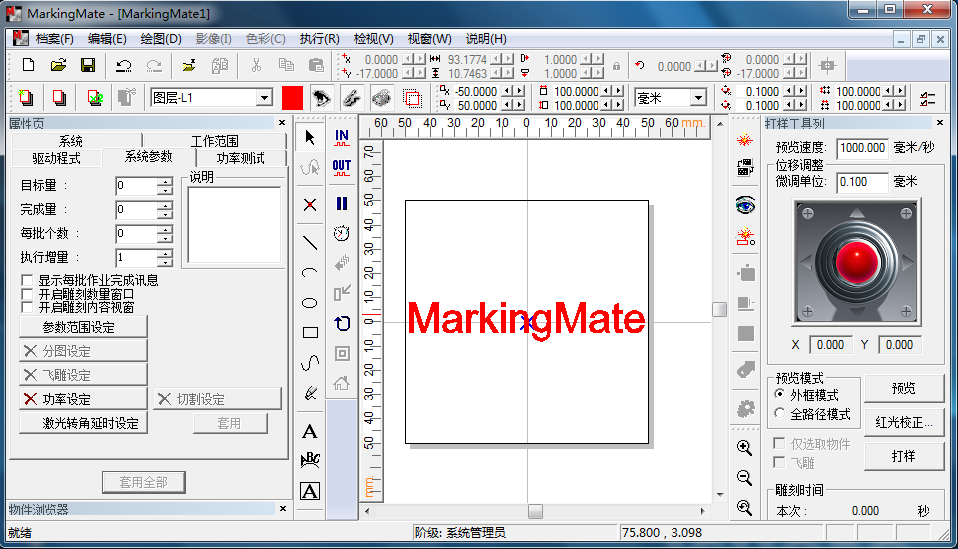

UMC4 Software Introduction refers to the software developed specifically for the UMC4 laser marking control card. It is used to design, control, and manage the laser marking process, helping users to perform efficient and precise laser marking tasks.

1. Overview of Software Features

The UMC4 software comes with the following core features:

1.1 Marking Design and Editing

Graphic Design: Users can design text, graphics, QR codes, barcodes, and other marking content within the software. It supports importing various file formats, such as DXF, BMP, PLT, etc.

Editing Tools: The software provides various editing tools such as rotation, scaling, alignment, and positioning, allowing users to easily adjust the size, position, and orientation of marking objects.

Font and Graphic Library: The software includes a rich font library and graphic elements, making it easier for users to use or modify existing templates.

1.2 Control and Parameter Adjustment

Laser Control: The software allows precise adjustment of laser parameters such as power, speed, frequency, and pulse width to meet the needs of different materials.

Multiple Workpiece Marking: It supports marking multiple workpieces or regions simultaneously, increasing work efficiency.

Real-Time Monitoring: The software provides real-time feedback and monitoring of the laser marking machine’s status, including laser power, current operating mode, remaining time, etc., ensuring smooth marking operations.

1.3 Processing Control

Time Management: The software can set the time for each marking task and automatically switch to the next task after completion, supporting batch processing.

Path Optimization: By optimizing paths and speeds, the software reduces processing time and improves production efficiency.

Auto Focus and Positioning: The software supports automatic focusing and positioning algorithms to ensure precise laser marking and prevent misalignment or errors.

1.4 User Interface

Graphical Interface: The software typically features a user-friendly graphical interface with intuitive operations. Users can complete most tasks through simple actions like clicking and dragging.

Multilingual Support: To accommodate users from different regions, the software usually provides multilingual interfaces, including Chinese, English, and other languages.

Personalized Settings: Users can customize the interface layout, shortcut keys, and default parameters to suit their personal preferences.

1.5 Data Management and Export

Task Management: The software allows users to create and save marking tasks, manage historical tasks, import files, and set task priorities.

Data Export: It supports exporting marking data in standard file formats, such as CSV and TXT, for future records and traceability.

1.6 Hardware Compatibility and Integration

PLC Integration: The UMC4 software supports integration with PLC (Programmable Logic Controllers), allowing the laser marking machine to work in sync with other automation equipment.

External Device Interfaces: Through interfaces like USB, RS232, and Ethernet, the software can connect to laser marking machines, sensors, industrial computers, and other devices to ensure smooth system operation.

2. Technical Support and Updates

Software Updates: The UMC4 software is regularly updated with new features and optimizations, offering more marking modes and enhanced control capabilities.

Technical Support: The developer provides technical support, including software installation, operation training, and troubleshooting services, ensuring users can use the software smoothly.

3. Application Fields

The UMC4 software is widely used in various industrial fields, including:

Automotive Industry: For precision marking of automotive components, such as car body parts, engine components, and accessories.

Electronics Industry: For marking circuit boards, components, chips, and other electronic devices.

Medical Industry: For laser marking medical devices, pharmaceuticals, and packaging, ensuring traceability and compliance.

Metal Processing Industry: For high-precision marking on metal materials, widely used in tools, parts, and equipment identification.

The integration of UMC4 software and hardware ensures that the laser marking machine not only provides high precision and efficiency but also meets the diverse needs of industrial production, enhancing overall automation levels.

UMC4 laser marking software do

UMC4 laser marking software do

ezcad2 64-bit system driver do

ezcad2 64-bit system driver do

ezcad2 32-bit system driver do

ezcad2 32-bit system driver do

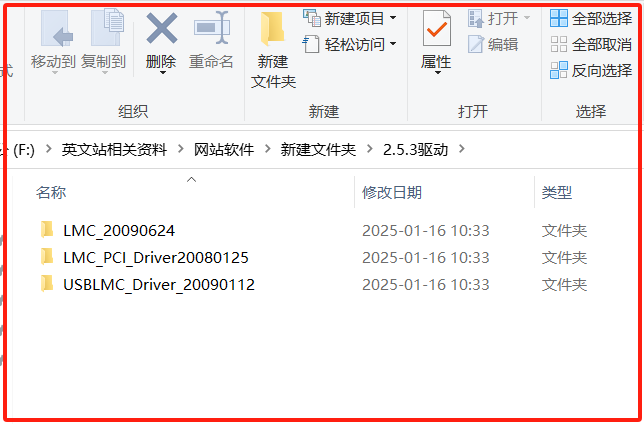

EZCAD2.5.3 Driver Download

EZCAD2.5.3 Driver Download