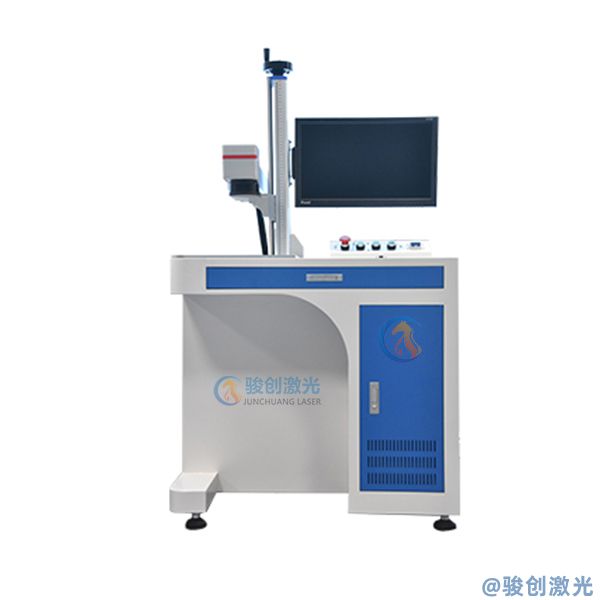

Metal material dedicated laser marking machine JC-GX-50

| If you don’t know which model to choose, please contact us directly! |

| We will provide you with the most reasonable solution! |

| Junchuang Laser is now recruiting regional agents, welcome to consult!! |

Model Specifications:

| Model | JC-GX-20 | JC-GX-30 | JC-GX-50 | JC-GX-100 |

|---|---|---|---|---|

| Average Power | 20W | 30W | 50W | 100W |

| Frequency Range | 20~200kHz | 20~200kHz | 50~200kHz | 50~200kHz |

| Marking Line Speed | 8000mm/s | 8000mm/s | 8000mm/s | 8000mm/s |

| Marking Area | 110×110mm (Optional) | 110×110mm (Optional) | 110×110mm (Optional) | 110×110mm (Optional) |

| Minimum Character Width | 0.1mm | 0.1mm | 0.1mm | 0.1mm |

| Repeatability Accuracy | <24 μrad | <24 μrad | <24 μrad | <24 μrad |

| Engraving Depth | 0.8mm (Depending on Material and Power) | 0.8mm (Depending on Material and Power) | 0.8mm (Depending on Material and Power) | 0.8mm (Depending on Material and Power) |

| Minimum Line Width | 0.06mm (Depending on Material) | 0.06mm (Depending on Material) | 0.06mm (Depending on Material) | 0.06mm (Depending on Material) |

| Power Supply | AC 220V/110V 50KHz | AC 220V/110V 50KHz | AC 220V/110V 50KHz | AC 220V/110V 50KHz |

Introduction to JunChuang Fiber Laser Marking Machine:

The JunChuang® series of marking machines utilize a 10mm incident spot size, providing clear and crack-free text input. The maximum speed reaches 1200MM/S, with a 20W industrial laser as the core power source, offering a lifespan of up to 100,000 hours.

This equipment employs JunChuang's® exclusively developed laser waveband interception module, which can intercept and filter out the harmonics and unstable wavebands in AC and DC power, ensuring a stable current waveband for the laser marking machine. Through JunChuang Laser's® exclusive technology enhancements and tuning, this equipment exhibits greater stability and durability compared to conventional laser marking machines. The JunChuang® industrial laser marking machine is manufactured according to industrial production standards, capable of continuous 24-hour uninterrupted operation, with a laser power fluctuation of <2%, stable power consumption, a laser movement tracking error of ≤110us, and a repeat positioning accuracy of <5μRad. The operating temperature range is from -15°C to +60°C.

Fiber laser marking machines utilize a laser beam to create marks on various material surfaces. The marking effect is achieved by evaporating the surface material to reveal the deeper layer, or causing physical changes in the surface material through optical energy to "etch" traces, or burning away part of the material to expose the desired etched patterns, text, barcodes, and other graphics.

Characteristics of Fiber Laser Marking Machines:

- Can process a wide range of metallic and non-metallic materials, especially advantageous for marking high-hardness, high-melting-point, and brittle materials.

- Non-contact processing, which does not damage the product and has no tool wear, resulting in high-quality marking.

- The laser beam is thin, with minimal material consumption during processing and a small thermally affected zone.

- High processing efficiency, 2-3 times that of traditional laser marking machines, computer-controlled, and easy to automate.

- Long lifespan, using a laser diode as the pump source, with an average operating time of up to 100,000 hours.

- Low operating costs, with an electro-optic conversion efficiency of up to 30% and a total power consumption of less than 500W, which is one-tenth of that of pump-source solid-state laser marking machines, significantly reducing energy consumption expenses.

- Maintenance-free operation.

Application Fields of Fiber Laser Marking Machines:

Electrical appliances, electronic communications, automotive and motorcycle parts, precision hardware, gift accessories, eyeglasses and watches, instruments and meters, and sanitary ware industries, not suitable for highly reflective materials.

Introduction to JunChuang's Galvo Laser Head System Technology:

The system utilizes position sensors, error amplifiers, power amplifiers, position discriminators, current integrators, etc., to enhance laser operating efficiency.

■ Differential photoelectric sensors detect the position of the motor rotor, featuring good linearity, small drift, high resolution, and high repeat positioning accuracy.

■ The 10mm mirror is designed with load considerations, and the motor assembly exhibits high precision, reasonable structure, small static friction coefficient, and small zero-point offset, ensuring good dynamic characteristics of the system.

■ The driver has position and speed lead detection functions, significantly improving the system's dynamic response efficiency and scanning speed.

■ Designed with overload, overcurrent, and reverse connection protection to make the system's operation more reliable.

■ The entire system adopts electromagnetic compatibility optimization design, with high signal-to-noise ratio and strong anti-interference ability.

■ Solves common issues such as galvo motor temperature drift, signal interference, and zero drift.

Performance Specifications:

| Specification | Value |

|---|---|

| Positioning Speed | 12000mm/s |

| Write Speed | 450cps |

| Response Time (1%) | 350us |

| Response Time (10% of Full Stroke) | 750us |

| Tracking Error | ≤110us |

| Accuracy and Error | |

| Linearity | 99.9% |

| Repeat Positioning Accuracy | <5μRad. |

| Gain Error | <5mRad. |

| Zero Point Offset (Batch Origin Error) | <5mRad. |

| Long-term Drift (Continuous Operation for 8 Hours) | <0.5mRad. |

| Proportional Drift | <40PPM/℃ |

| Zero Drift | <15μRad./℃ |

| Laser Input Aperture | 10mm |

Explanation of Galvo Mechanism:

A galvo is a special oscillating motor. The principle involves generating torque in a magnetic field when a energized coil is energized. Unlike a rotating motor, its rotor applies a restoring torque through the electromagnetic field, which is proportional to the angle by which the rotor deviates from the equilibrium position. When the coil is energized, the rotor deflects to a certain angle, where the electromagnetic torque is equal to the restoring torque, so it cannot rotate like an ordinary motor but can only deflect, and the deflection angle is proportional to the current.

Control Circuit Principle:

When an input position signal is received, the motor will oscillate to a certain angle according to the conversion ratio between voltage and angle.

The entire process adopts closed-loop feedback control, with the joint action of five major control circuits: position sensors, error amplifiers, power amplifiers, position discriminators, and current integrators.

Comparison Table of Processing Materials for JunChuang Series Models:

| Model | Raycus | Raycus | Raycus | JPT LP | JPT LP | JPT LP | JPT M7 (MOPA) | JPT M7 (MOPA) | JPT M7 (MOPA) |

|---|---|---|---|---|---|---|---|---|---|

| Material | 20W | 30W | 50W | 20W | 30W | 50W | 20W | 30W | 50W |

| Gold/Silver | X | O | O | X | O | O | X | O | O |

| Copper | X | O | O | X | O | O | X | O | O |

| White Marking on Copper | X | O | O | X | O | O | X | O | O |

| Black Marking on Copper | X | O | O | X | O | O | X | O | O |

| White Marking on Anodized Aluminum | O | O | O | O | O | O | O | O | O |

| Black Marking on Anodized Aluminum | X | X | X | X | X | X | O | O | O |

| Color Marking on Stainless Steel | X | X | X | X | X | X | O | O | O |

| Mirror Coating | O | O | O | O | O | O | O | O | O |

| Slate | O | O | O | O | O | O | O | O |

JunChuang Laser Model Parameters

Laser Model Specifications

| Model | JC-GX-20 | JC-GX-30 | JC-GX-50 | JC-GX-100 |

|---|---|---|---|---|

| Average Power | 20W | 30W | 50W | 100W |

| Frequency Range | 20~200kHz | 20~200kHz | 50~200kHz | 50~200kHz |

| Engraving Speed | 8000mm/s | 8000mm/s | 8000mm/s | 8000mm/s |

| Marking Area | 110×110mm (optional) | 110×110mm (optional) | 110×110mm (optional) | 110×110mm (optional) |

| Minimum Character Width | 0.1mm | 0.1mm | 0.1mm | 0.1mm |

| Repeat Accuracy | <24 μrad | <24 μrad | <24 μrad | <24 μrad |

| Engraving Depth | 0.8mm (varies with material and power) | 0.8mm (varies with material and power) | 0.8mm (varies with material and power) | 0.8mm (varies with material and power) |

| Minimum Line Width | 0.06mm (material-dependent) | 0.06mm (material-dependent) | 0.06mm (material-dependent) | 0.06mm (material-dependent) |

| Power Supply | AC 220V/110V 50KHz | AC 220V/110V 50KHz | AC 220V/110V 50KHz | AC 220V/110V 50KHz |

Material Processing Capability Comparison

| Model | Raycus | Raycus | Raycus | JPT LP | JPT LP | JPT LP | JPT M7 (MOPA) | JPT M7 (MOPA) | JPT M7 (MOPA) |

|---|---|---|---|---|---|---|---|---|---|

| Material | 20W | 30W | 50W | 20W | 30W | 50W | 20W | 30W | 50W |

| Gold/Silver | X | O | O | X | O | O | X | O | O |

| Copper | X | O | O | X | O | O | X | O | O |

| White Marking on Copper | X | O | O | X | O | O | X | O | O |

| Black Marking on Copper | X | O | O | X | O | O | X | O | O |

| White Marking on Anodized Aluminum | O | O | O | O | O | O | O | O | O |

| Black Marking on Anodized Aluminum | X | X | X | X | X | X | O | O | O |

| Color Marking on Stainless Steel | X | X | X | X | X | X | O | O | O |

| Mirror Coating | O | O | O | O | O | O | O | O | O |

| Slate | O | O | O | O | O | O | O | O | O |

| Leather | O | O | O | O | O | O | O | O | O |

| Black Marking on Stainless Steel | O | O | O | O | O | O | O | O | O |

| Black Marking on ABS | O | O | O | O | O | O | O | O | O |

| Cardboard | O | O | O | O | O | O | O | O | O |

Laser Power Parameters

| Laser | 20W | 30W | 50W | |

|---|---|---|---|---|

| Wavelength (nm) | 1064±5 | 1064±5 | 1064±5 | |

| Polarization | Random | Random | Random | |

| Optical Isolator | Yes | Yes | Yes | |

| Average Output Power (W) | ≥21 | ≥33 | ≥53 | |

| Single Pulse Energy (mJ) | 0.67 mJ@30KHz | 0.75 mJ@40KHz | 1mJ@50KHz | |

| Beam Quality (M²) | ≤1.6 | ≤1.6 | ≤1.6 | |

| Spot Diameter (mm) | 6~8 | 6~8 | 6~8 | |

| Pulse Width (ns) | 110~140@30KHz | 110~130@40KHz | 120~150@50KHz | |

| Repetition Rate (kHz) | 30-60 | 40-60 | 50-100 | |

| Output Power Adjustment Range (%) | 10~100 | 10~100 | 10~100 | |

| Output Optical Isolation Length (m) | 3.2±0.2 | 3.2±0.2 | 3.2±0.2 | |

| Operating Voltage (VDC) | 24±1 | 24±1 | 24±1 | |

| Input Power (at 20℃) (W) | <200 | <240 | <340 | |

| Cooling Method | Air-cooled | Air-cooled | Air-cooled | Air-cooled |

| Storage Temperature (℃) | -10~60 | -10~60 | -10~60 | |

| Humidity (%) | 30~85 | 30~85 | 30~85 |

Laser Head Parameters

| Speed and Accuracy | Value |

|---|---|

| Positioning Speed | 12000mm/s |

| Writing Speed | 450cps |

| Response Time (1%) | 350us |

| Response Time (10% of Full Stroke) | 750us |

| Tracking Error | ≤110us |

| Accuracy and Error | |

| Linearity | 99.9% |

| Repeated Positioning Accuracy | <5μRad. |

| Gain Error | <5mRad. |

| Zero Point Drift (Batch Origin Error) | <5mRad. |

| Long-term Drift (Continuous Operation for 8 Hours) | <0.5mRad. |

| Proportional Drift | <40PPM/℃ |

| Zero Drift | <15μRad./℃ |

| Laser Input Aperture | 10mm |

This document provides an overview of JunChuang laser models, including their specifications, material processing capabilities, power parameters, and laser head parameters.