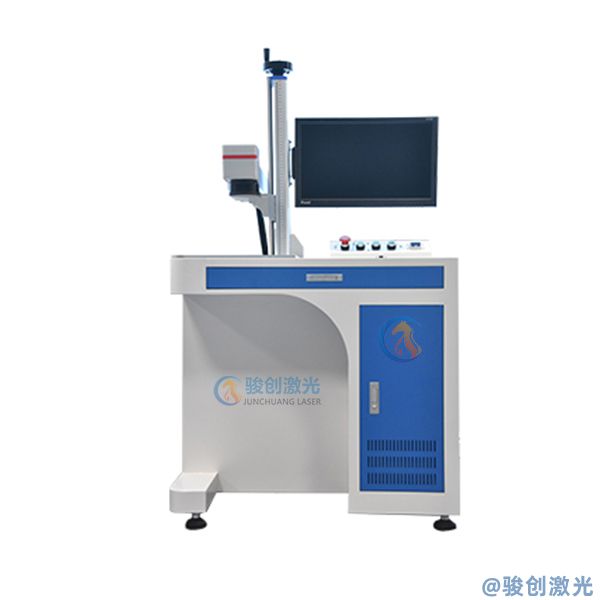

MOPA laser marking machine

| If you don’t know which model to choose, please contact us directly! |

| We will provide you with the most reasonable solution! |

| Junchuang Laser is now recruiting regional agents, welcome to consult!! |

The MOPA (Master Oscillator Power Amplifier) fiber laser marking machine is an advanced laser marking equipment that adopts MOPA technology. Its technical characteristics are mainly reflected in the following aspects:

I. Independently Adjustable Pulse Width and Repetition Rate

The MOPA fiber laser has unique pulse shape control capabilities, with its pulse width and repetition rate being independently controllable. The pulse width has a wide adjustment range, typically between 2 nanoseconds (ns) and 500 nanoseconds (ns), allowing flexible adjustment according to different processing requirements. A narrower pulse width means shorter interaction time between the laser and the material, resulting in a smaller heat-affected zone and higher processing precision.

At the same time, the repetition rate range of the MOPA fiber laser is also wide, reaching high-frequency outputs in the megahertz (MHz) range. A high repetition rate implies high processing efficiency, and even under high-frequency conditions, the MOPA laser can maintain high peak power characteristics, ensuring consistent marking effects.

II. Achieving High-Precision and High-Quality Processing

Due to the MOPA fiber laser's ability to precisely control pulse width and repetition rate, it can achieve high-precision and high-quality processing. It excels in fields such as fine marking, blackening of aluminum oxide, and color marking on stainless steel. For example, in the processing of stripping the anodic layer on the surface of aluminum oxide sheets, the MOPA laser uses small pulse width parameters, allowing the laser to interact with the material for a shorter time while having sufficient energy to remove the anodic layer, ensuring processing quality and avoiding material deformation.

III. Color Laser Marking Capability

The MOPA fiber laser marking machine also possesses color laser marking capability, which is one of its unique technical advantages. By adjusting the laser beam parameters on metal materials such as stainless steel, chromium, and titanium, the color of the material's surface layer can be changed, achieving rich and colorful decorative effects. This technology brings a new marking method to industries such as stainless steel products, allowing for the free editing of various text and patterns, which is both environmentally friendly and increases the added value of products.

IV. Wide Applicability and Flexibility

The MOPA fiber laser marking machine is suitable for precise marking processes on both metal and non-metal materials, such as digital product components, mobile phone keys, transparent keys, electronic components, integrated circuits (ICs), plastic keys, transparent plastic keys, glasses, watches, jewelry, automotive parts, and bag accessories. Its wide applicability and flexibility make the MOPA fiber laser marking machine widely used in multiple industries.

V. High Performance and Long Lifespan

The MOPA fiber laser marking machine adopts a high-performance fiber laser and an advanced control system, featuring good beam quality, fine lines, and small spot sizes. At the same time, the machine operates stably with a lifespan of up to ten years, meeting the demands of long-term and high-intensity production.

In summary, the MOPA fiber laser marking machine exhibits strong competitiveness in the laser marking field with its unique pulse shape control capabilities, high-precision and high-quality processing effects, color laser marking capabilities, and wide applicability and flexibility. As technology continues to advance and application fields continue to expand, the MOPA fiber laser marking machine will play an important role in more industries.

| Laser Type | MOPA Fiber Laser |

| Wavelength | Typically 1064nm (may vary depending on specific model) |

| Pulse Width Range | 2ns to 500ns (adjustable) |

| Repetition Rate Range | Up to MHz level (adjustable) |

| Peak Power | Varies depending on model and configuration, typically high for precise marking |

| Beam Quality (M²) | Excellent, ensuring fine line width and high precision |

| Spot Size | Small, allowing for high-resolution marking |

| Marking Speed | High, due to high repetition rate and efficient laser energy utilization |

| Marking Depth | Adjustable, depending on material type, thickness, and laser parameters |

| Applicable Materials | Metals (e.g., stainless steel, aluminum, titanium), plastics, and other non-metals |

| Control System | Advanced, with user-friendly interface for easy operation and parameter adjustment |

| Lifespan | Up to 10 years, depending on usage and maintenance |

| Additional Features | Color laser marking capability, high stability, and reliability |