MAX Fiber Laser Marking Machine (20W / 30W / 50W)

| If you don’t know which model to choose, please contact us directly! |

| We will provide you with the most reasonable solution! |

| Junchuang Laser is now recruiting regional agents, welcome to consult!! |

1. Product Overview

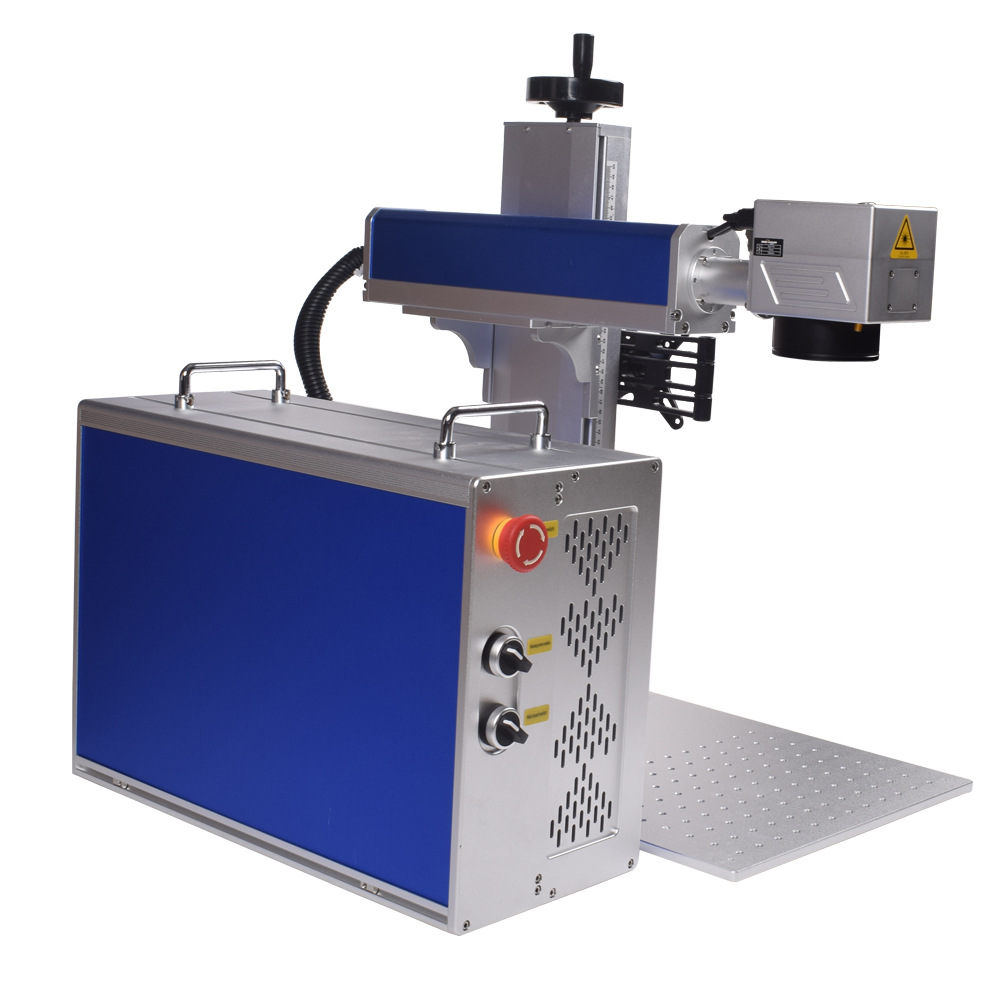

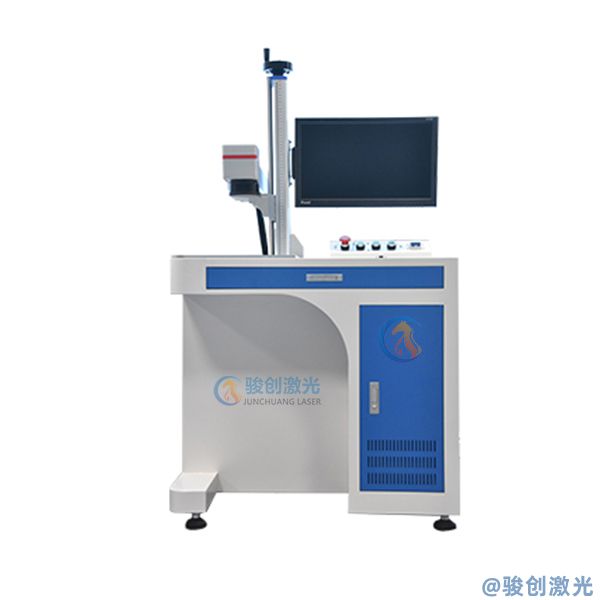

The MAX Fiber Laser Marking Machine is a high-performance industrial marking equipment equipped with a MAX Photonics fiber laser source from Shenzhen, China.

It features stable output, excellent beam quality, and high marking precision. The system offers fast, accurate, and permanent marking on metals and certain non-metal materials.

With compact design and reliable operation, it is widely used in electronics, automotive, tools, machinery, medical, and communication industries, providing a cost-effective and durable marking solution.

2. Main Features

High-Performance MAX Laser Source

Integrated MAX Photonics fiber laser, known for stable power output, high pulse energy, and excellent beam quality.

High photoelectric conversion efficiency (≥70%), low power consumption, and minimal heat generation.

Long operational lifespan of over 100,000 hours, maintenance-free.

Delivers fine marking results with sharp edges and high contrast, ideal for precision components.

Flexible Power Options

Available in 20W / 30W / 50W power levels to meet various marking requirements:

20W – Suitable for plastic and lightweight metal engraving.

30W – Perfect for medium-depth marking on stainless steel, aluminum, brass, and alloy.

50W – Designed for deep engraving, black marking on anodized aluminum, and high-speed production lines.

Intelligent Control System

Comes with professional EZCAD control software supporting both English and Chinese interfaces.

Compatible with multiple graphic and text formats: PLT, DXF, BMP, AI, JPG, PNG, TTF, etc.

Supports serial numbers, QR codes, barcodes, logos, and automatic date or batch marking.

Can be integrated into automated production lines for continuous (flying) marking.

Compact and Reliable Design

Modular and ergonomic design with small footprint, easy installation, and maintenance.

High-speed digital galvanometer ensures fast and precise marking up to 7000 mm/s.

Fully enclosed optical system — dustproof, vibration-resistant, and stable for factory environments.

Air-cooled system ensures efficient heat dissipation without additional cooling units.

Wide Application Range

Applicable for various metal and non-metal materials, including:

Metals: Stainless steel, aluminum, copper, brass, titanium, silver, gold, iron, etc.

Non-metals: ABS, PVC, nylon, PC, PBT, and other plastics.

Industries: Electronics, automotive, hardware tools, machinery, medical instruments, communication equipment, and jewelry.

3. Technical Specifications

| Item | Specification |

|---|---|

| Laser Brand | MAX Photonics |

| Laser Type | Fiber Laser |

| Output Power | 20W / 30W / 50W |

| Wavelength | 1064 nm |

| Beam Quality (M²) | < 1.5 |

| Marking Area | 110×110mm (Optional: 150×150mm / 175×175mm / 200×200mm) |

| Marking Speed | ≤ 7000 mm/s |

| Minimum Line Width | 0.01 mm |

| Minimum Character | 0.15 mm |

| Repeat Accuracy | ±0.001 mm |

| Cooling Method | Air Cooling |

| Control Software | EZCAD (English/Chinese) |

| Supported Formats | PLT, DXF, BMP, JPG, PNG, TTF |

| Power Supply | AC 110V / 220V ±10%, 50/60Hz |

| Working Environment | 0–40°C, Humidity < 80% |

| Laser Lifetime | ≥100,000 hours |

4. Product Advantages

Permanent, high-contrast marking — resistant to wear and corrosion.

Fast marking speed for mass production.

Low energy consumption and zero consumables.

Maintenance-free laser source with ultra-long service life.

Compact, modular, and easy to integrate with automation systems.

Customizable design and OEM/ODM available.

5. Optional Configurations

Electric or motorized lifting column

Flying (online) marking system for conveyor lines

Rotary fixture for cylindrical parts

3D dynamic focusing system for curved surfaces

Safety enclosure and fume extraction unit

6. Typical Applications

Stainless steel tool and knife logo engraving

Aluminum profile barcode & QR code marking

Copper connector serial number marking

Plastic shell character engraving

Medical equipment identification and batch coding