How to adjust the parameters of a UV laser marking machine

UV laser marking machines (UV lasers) are high-precision devices widely used for marking delicate and thin materials. They are characterized by short wavelengths (typically around 355nm) and can mark hard and heat-sensitive materials such as glass, plastic, ceramics, and silicon wafers.

Adjusting the parameters of a UV laser marking machine requires setting based on specific marking needs, material properties, and process requirements. Below are the common parameters for UV laser marking machines and how to adjust them:

1. Laser Power

Effect: Laser power determines the energy output of the laser and directly affects the depth, color, and quality of the marking.

Adjustment Method: Adjust the power setting in the software. Higher power means more energy, leading to deeper markings. Too high a power may cause burning or deformation, while too low may result in unclear markings.

Recommendation: Typically, UV laser marking machines are set between 20% and 80% power, depending on the material type and desired marking effect.

2. Pulse Frequency

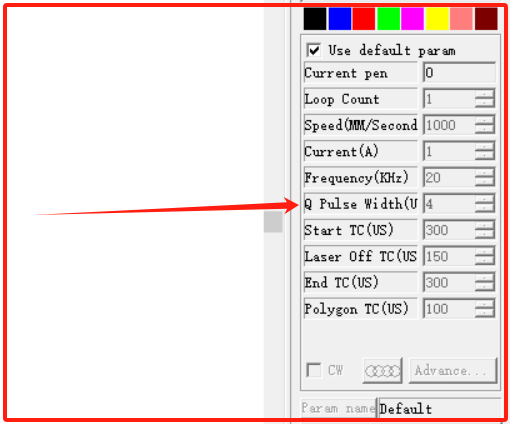

Effect: Pulse frequency refers to the number of pulses the laser emits per second and affects marking speed and quality.

Adjustment Method: Adjust the pulse frequency in the software, usually measured in kHz (kilohertz). A higher frequency results in faster marking, but may reduce the fine details of the marking.

Recommendation: For softer materials, a higher frequency (30-100 kHz) is suitable, while for harder materials, a lower frequency (10-20 kHz) ensures clearer, finer marking.

3. Marking Speed

Effect: Marking speed determines how fast the laser moves over the material's surface, directly affecting clarity and efficiency.

Adjustment Method: Adjust the marking speed based on the marking requirements. Too fast a speed may result in unclear markings, while too slow may lower production efficiency.

Recommendation: The typical marking speed is between 300-2000 mm/s. For intricate designs or high-precision marks, reduce the speed; for simple text or markings, increase the speed.

4. Focusing Lens

Effect: The focusing lens controls the size of the laser focus point, which affects the detail and accuracy of the marking.

Adjustment Method: Choose the appropriate focal length and focus size for the material. A smaller focus point leads to finer markings, while a larger focus may reduce marking clarity.

Recommendation: Common focal lengths for UV lasers are 100mm, 160mm, or 254mm. For fine marking, a smaller focal length lens should be used to obtain a finer focus.

5. Line Width

Effect: Line width determines the width of each scan the laser makes during the marking process, influencing the marking's quality.

Adjustment Method: Adjust the line width parameter in the software. Typically, smaller line widths result in finer details but at a lower speed.

Recommendation: Line width is usually set between 0.01mm to 0.1mm, depending on the pattern and material requirements.

6. Overlap

Effect: Overlap refers to the degree of overlap between different lines during the laser scan, which affects marking quality and sharpness.

Adjustment Method: Adjust the scanning strategy in the software to increase or decrease overlap between lines.

Recommendation: Increasing overlap can improve marking quality, but excessive overlap reduces marking speed. Generally, overlap is set between 10%-30%.

7. Marking Depth

Effect: Marking depth is mainly determined by a combination of laser power, frequency, and speed. Proper marking depth ensures that patterns or text are visible and clear.

Adjustment Method: Control the depth by adjusting laser power, frequency, and speed. Higher power and slower speed typically create deeper marks.

Recommendation: Different materials require different depths. For hard materials like glass or ceramics, higher power and slower speed are needed, while for softer materials like plastic, lower power and higher speed are suitable.

8. Cooling System

Effect: UV laser marking machines typically come with a cooling system to prevent overheating, which affects both device stability and marking quality.

Adjustment Method: Ensure the cooling system is functioning correctly, and adjust the temperature control to keep it within an optimal range.

Recommendation: The typical working temperature range is between 18°C to 28°C. Overheating can cause instability and degrade marking quality.

9. Material Selection and Testing

Effect: Different materials have different laser absorption properties, so adjusting parameters requires optimization based on the material's characteristics.

Adjustment Method: Conduct trial marking tests to determine the best combination of parameters.

Recommendation: For different materials (e.g., metals, plastics, glass), parameters should be adjusted according to the specific material requirements to achieve optimal marking results.

Conclusion

Adjusting the parameters of a UV laser marking machine is a process that takes into account the material, desired marking effect, and production efficiency. By appropriately adjusting parameters such as power, frequency, speed, and focal length, users can achieve detailed, clear marking results. In practical applications, users should repeatedly adjust and test parameters to achieve the best marking quality.

laser marking machine for meta

laser marking machine for meta

laser marking machine price in

laser marking machine price in

HS code information of laser m

HS code information of laser m

20w fiber laser marking machin

20w fiber laser marking machin