Flying laser marking machine used on drug paper boxes

Introduction to Flight Laser Marking Machines for Pharmaceutical Boxes

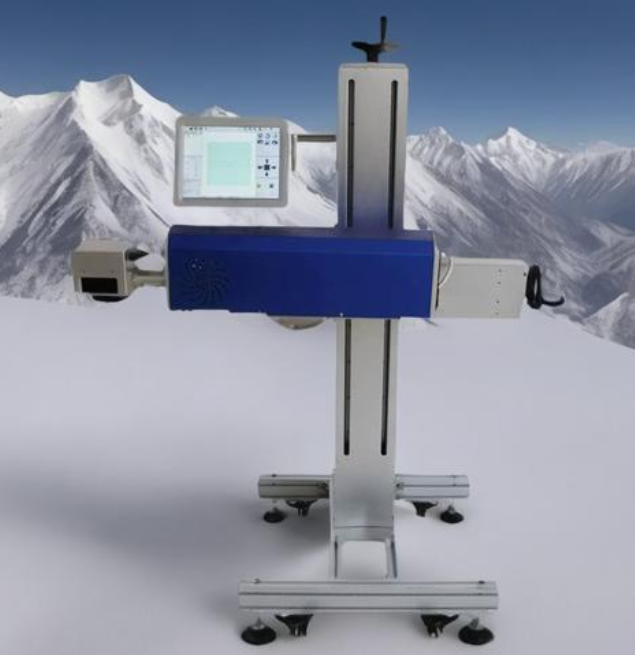

In the pharmaceutical industry, clear and durable marking on packaging is crucial for product traceability, safety, and compliance with regulatory standards. Flight laser marking machines are designed to mark high-quality, precise information, such as production dates, batch numbers, serial numbers, and expiration dates, directly onto pharmaceutical boxes without contact. These machines offer a non-destructive, environmentally friendly solution for marking pharmaceutical packaging.

Advantages of Using Flight Laser Marking Machines for Pharmaceutical Boxes

High Precision and Clarity

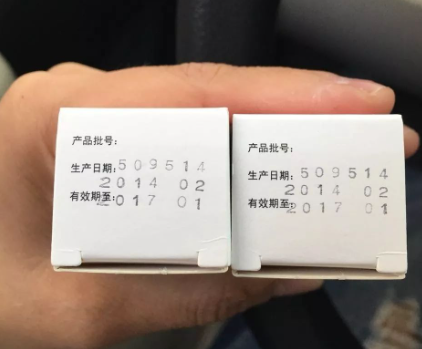

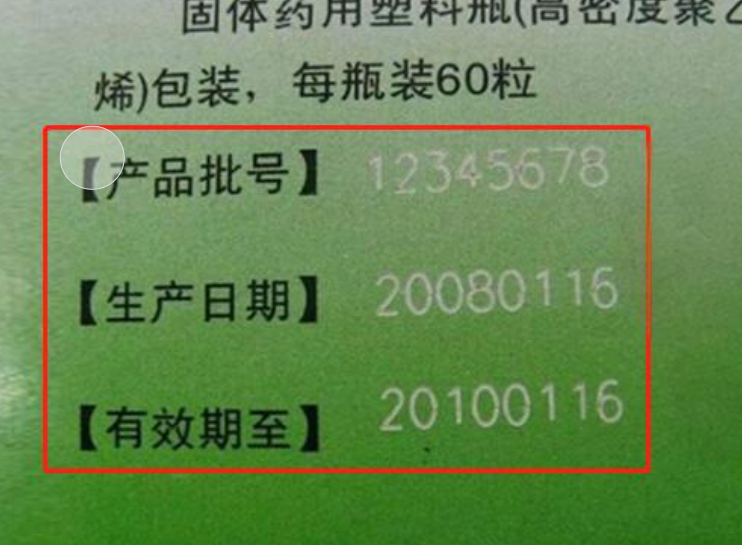

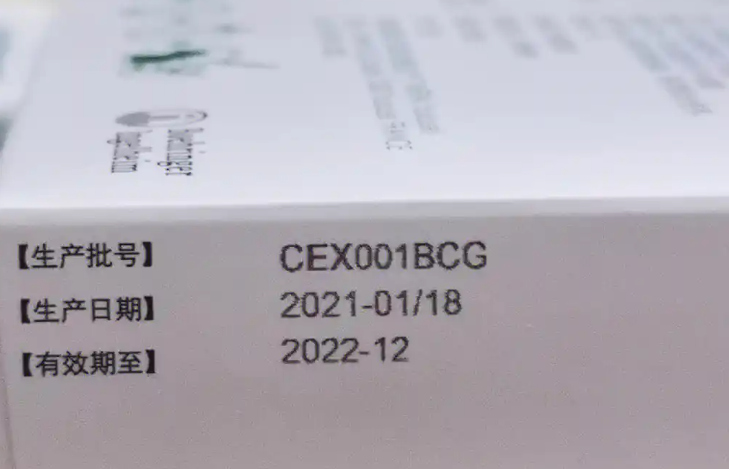

Flight laser marking machines ensure highly accurate and legible markings, even on small and intricate surfaces. This is especially important for pharmaceutical boxes, which often require small fonts for batch numbers, production dates, and expiry dates.Non-Contact and Non-Damaging

The laser marking process is non-contact, which means there is no physical wear or damage to the pharmaceutical packaging. This is ideal for delicate materials like pharmaceutical boxes, which need to maintain their appearance and integrity.Durability and Longevity

Laser markings are permanent and resistant to smudging, fading, or being erased. Pharmaceutical products are often stored for long periods, and the markings need to remain clear throughout their lifecycle, even under varying conditions of temperature, humidity, and light exposure.Fast and Efficient

Flight laser marking machines can be integrated into high-speed production lines, providing quick and efficient marking. They can mark a large number of pharmaceutical boxes in a short amount of time without slowing down the production process.

Environmentally Friendly

Unlike traditional printing methods, which require ink and solvents, flight laser marking machines do not use consumables. This makes the process more environmentally friendly, as it produces no waste and reduces the need for chemical substances.Compliance with Regulatory Standards

Laser markings can include important information like serial numbers, barcodes, and QR codes, which are often required for compliance with pharmaceutical regulations. These features help ensure traceability and authenticity, which are vital in the pharmaceutical industry.

Applications of Flight Laser Marking Machines for Pharmaceutical Boxes

Marking Production Dates and Expiry Dates

Flight laser marking machines can mark production and expiry dates directly onto pharmaceutical boxes, ensuring that consumers and distributors have accurate and tamper-proof information.Batch Numbers and Serial Numbers

Laser machines can mark batch numbers and unique serial numbers, which are essential for product recall and traceability. This helps maintain safety and accountability in the pharmaceutical supply chain.Barcode and QR Code Marking

Flight laser marking machines are capable of marking barcodes or QR codes on pharmaceutical boxes. These codes provide easy access to product information, including batch traceability, authentication, and manufacturing details.Branding and Anti-Counterfeiting

Laser technology can be used to engrave unique brand logos, security marks, or micro-text onto pharmaceutical packaging, providing a strong defense against counterfeiting and ensuring the authenticity of the product.

Key Features of Flight Laser Marking Machines

High-Speed Marking

Flight laser marking machines are designed for high-speed marking, making them ideal for pharmaceutical packaging lines where efficiency is critical. They can mark hundreds of boxes per minute without compromising quality.Customization and Flexibility

These machines can be easily adjusted to mark various types of information, including different fonts, logos, and codes, making them highly adaptable to the specific needs of the pharmaceutical industry.Laser Source Options

Flight laser marking machines use different types of lasers, such as fiber lasers, CO2 lasers, and UV lasers, allowing them to work with a variety of materials commonly used in pharmaceutical packaging, such as paperboard, plastic, and aluminum.Integration with Production Lines

These marking machines can be integrated with existing pharmaceutical production lines, minimizing disruptions to the workflow and ensuring that all packaging is marked quickly and accurately.

Conclusion

Flight laser marking machines offer an advanced, precise, and efficient solution for marking pharmaceutical boxes. They help ensure that critical information such as production dates, batch numbers, and serial numbers are clearly and permanently marked on the packaging. With their speed, precision, and environmental benefits, flight laser marking machines play a crucial role in the pharmaceutical industry, helping companies meet regulatory requirements, improve traceability, and enhance product safety.

laser marking machine for meta

laser marking machine for meta

laser marking machine price in

laser marking machine price in

HS code information of laser m

HS code information of laser m

20w fiber laser marking machin

20w fiber laser marking machin