Introduction to Laser Coding Machines in Beverage Industry Factories

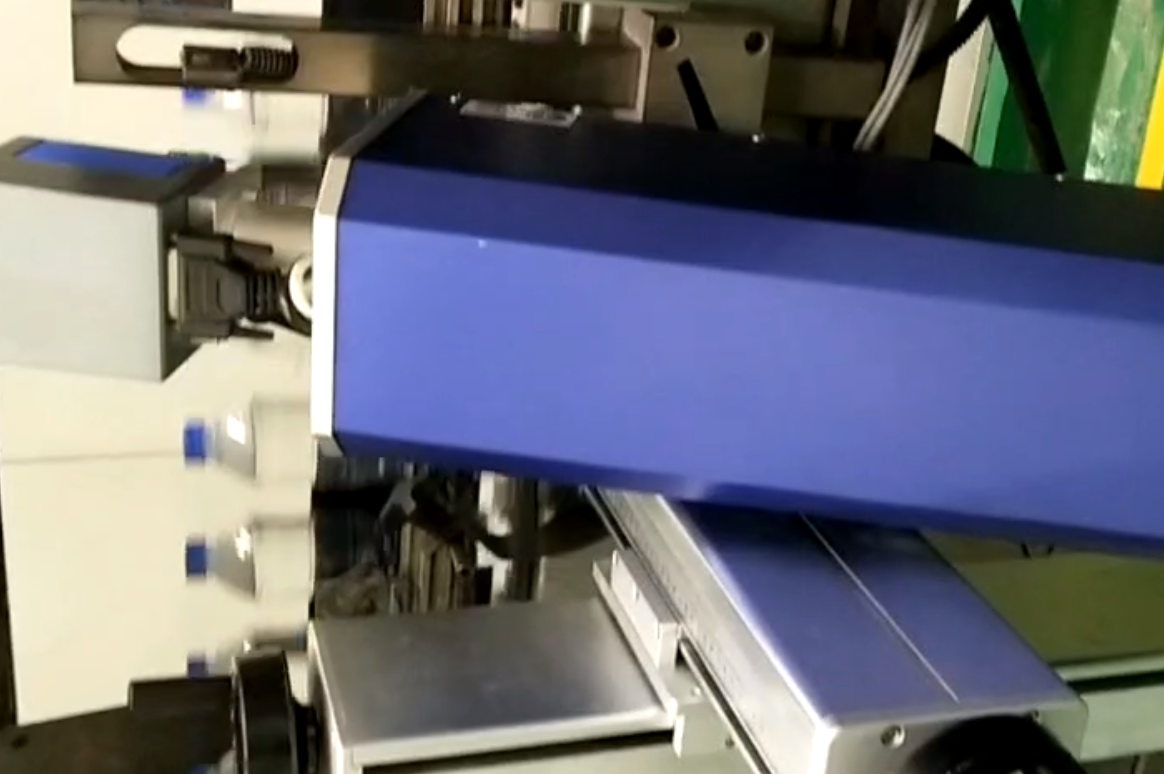

Laser coding machines are widely used in beverage industry factories due to their high efficiency, precision, and environmentally friendly marking solutions. Beverage industries need to mark production dates, expiry dates, batch numbers, barcodes, and QR codes on product packaging. Laser coding machines, with their non-contact, durable, and high-quality marking features, have become ideal equipment in beverage production lines.

Below is a detailed introduction to the application and advantages of laser coding machines in beverage industry factories:

1. Working Principle

Laser coding machines work by directing high-energy laser beams onto the surface of beverage bottles, cans, or other packaging materials. The laser beam instantly evaporates a part of the material's surface, leaving behind clear, permanent marks. Unlike traditional inkjet printing technology, laser coding machines do not require ink or other solvents, making them especially suitable for the food and beverage industry, where hygiene standards are critical.

2. Main Applications

In the beverage industry, laser coding machines are mainly used in the following areas:

Production Date and Expiry Date Marking

Laser coding machines can precisely mark production dates, expiry dates, and shelf life, ensuring product traceability and safety.Batch Numbers and Serial Numbers

Laser coding machines can clearly mark batch numbers and serial numbers for easy tracking and quality control.Barcodes and QR Codes

Laser coding machines can efficiently mark barcodes or QR codes on beverage packaging, facilitating warehouse management, logistics, and sales tracking.Brand Logos and Graphics

Laser marking can add brand logos, promotional graphics, or trademarks on bottles or cans, enhancing brand recognition and product appearance.

3. Features of Laser Coding Machines

Laser coding machines offer several notable advantages for use in the beverage industry:

High Speed and Efficiency

Laser coding machines have fast marking speeds, making them ideal for high-speed beverage production lines. They can work 24/7 to meet large-scale production needs.High Precision and Clarity

Laser coding machines provide very high precision and clarity, enabling the marking of small fonts and complex patterns, meeting the beverage industry’s requirements for detail and legibility.Non-contact, No Consumables

Laser coding machines mark without physical contact, eliminating the need for ink, solvents, or other consumables. This reduces environmental pollution and prevents ink residue or contamination of packaging, ensuring hygiene and safety.Eco-friendly and Energy-efficient

Laser coding machines use laser technology, which does not produce harmful gases or waste, making them compliant with green production standards. Additionally, they consume less energy, helping reduce operating costs.Strong Adaptability

Laser coding machines can be used on various beverage packaging materials such as glass bottles, aluminum cans, and plastic bottles. They provide stable and long-lasting marking, adapting to different production environments.

4. Food Safety and Quality Control

The beverage industry has strict requirements for food safety and product traceability. The use of laser coding machines ensures the following:

Product Traceability

Laser coding machines mark production dates, batch numbers, serial numbers, and other information for easy product traceability, ensuring that quality issues can be quickly identified and resolved.Anti-Counterfeit Features

Laser coding machines can add anti-counterfeit markings to packaging, preventing counterfeit products from entering the market and protecting the brand and consumer rights.

5. Equipment Selection and Configuration

When selecting a laser coding machine for a beverage factory, the following factors should be considered:

Laser Type

Choose the appropriate laser type based on the packaging material. CO₂ lasers are suitable for plastic and glass bottles, while fiber lasers are ideal for metal packaging (e.g., aluminum cans).Marking Content and Complexity

If complex patterns, QR codes, or small fonts need to be marked, select a laser coding machine with higher resolution and precision to ensure clarity.Production Line Compatibility

The laser coding machine should integrate smoothly with the beverage production line’s speed and equipment to ensure seamless operation during marking.Environmental and Safety Requirements

Choose laser coding machines that meet environmental standards, are non-toxic, and consume low energy to ensure their suitability for the beverage production environment.

6. Advantages of Laser Coding Machines in the Beverage Industry

In the beverage industry, laser coding machines offer several significant advantages:

Increased Production Efficiency

Laser coding machines can quickly and precisely mark products, reducing manual intervention and increasing production efficiency.Ensuring Product Hygiene and Safety

Since there is no need for ink or other solvents, laser coding machines eliminate the risk of ink residue or contamination, ensuring that beverage products meet hygiene standards.Lower Long-term Operating Costs

As there are no consumables such as ink or labels required, laser coding machines have lower operating costs and also incur lower maintenance costs, making them suitable for long-term use.Enhancing Brand Image

Clear markings, attractive graphics, and anti-counterfeit features improve brand competitiveness, building consumer trust and brand loyalty.

Conclusion

Laser coding machines in beverage industry factories not only improve production efficiency and product traceability but also ensure the hygiene, safety, and environmental compliance of beverage products. As the beverage industry continues to focus on quality control and production efficiency, laser coding machines have become essential equipment on modern beverage production lines.

laser marking machine for meta

laser marking machine for meta

laser marking machine price in

laser marking machine price in

HS code information of laser m

HS code information of laser m

20w fiber laser marking machin

20w fiber laser marking machin