Laser Coding Machines for Pharmaceutical Factories: Overview and Applications

Laser coding machines play a crucial role in the pharmaceutical industry, used to mark essential information on packaging such as batch numbers, production dates, expiration dates, barcodes, QR codes, and anti-counterfeiting details. Their high precision, permanence, and consumable-free operation make them an ideal choice for meeting the industry's strict regulations and quality standards.

Key Features of Laser Coding Machines

High Precision and Clarity

- Laser coders can achieve high-resolution markings on various pharmaceutical packaging materials, ensuring information is readable and scannable.

Permanent Markings

Laser markings are resistant to abrasion, water, corrosion, and high temperatures, ensuring traceability throughout the product's lifecycle.

Consumable-Free and Eco-Friendly

- Unlike traditional coding systems, laser coders do not require ink, solvents, or ribbons, reducing operating costs and chemical waste, aligning with environmental standards.

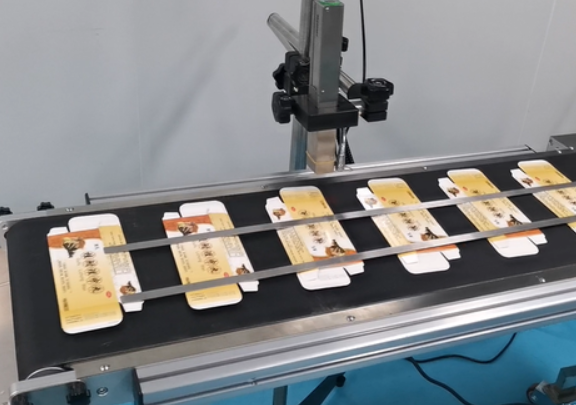

High-Speed Production Support

- Laser coders operate seamlessly on high-speed production lines without slowing down the packaging process, making them suitable for large-scale pharmaceutical manufacturing.

Ease of Integration

- These machines can be integrated into automated production lines and data management systems (e.g., ERP and MES systems), supporting real-time data updates and dynamic coding.

Compliance with Regulations

- The pharmaceutical industry demands strict traceability and clarity standards (e.g., per GMP and Drug Administration laws). Laser coders fully meet these requirements, including serialization and anti-counterfeiting features.

Compatible Packaging Materials

Laser coding machines are compatible with a wide range of materials commonly used in the pharmaceutical industry:

- Glass: Vials, bottles.

- Plastic: Blister packs, ampoules, and outer packaging.

- Metal: Aluminum foil, caps, and tubes.

- Paperboard: Cartons and labels.

- Flexible Packaging: Aluminum-plastic composite films.

Types of Laser Coding Machines

Depending on the materials and marking needs, pharmaceutical factories typically use the following types of laser coders:

UV Laser Coders

- Features: Low heat, non-damaging marking.

- Best For: Transparent or heat-sensitive materials, such as glass and plastic.

- Advantages: High-contrast, fine markings suitable for small fonts and intricate patterns on pharmaceutical packaging.

CO₂ Laser Coders

- Features: Ideal for non-metallic materials.

- Best For: Paperboard cartons, labels, and blister packs.

- Advantages: High-speed marking, suitable for mass production.

Fiber Laser Coders

- Features: High power, suitable for metals.

- Best For: Aluminum caps, foil seals, and certain plastic materials.

- Advantages: Durable markings, ideal for metal surfaces.

Typical Applications in the Pharmaceutical Industry

Batch Numbers and Expiration Dates

- Marking production dates, batch numbers, and expiration dates on packaging for traceability.

Barcodes and QR Codes

- For product tracking, anti-counterfeiting, and inventory management.

Serialization

- Assigning unique serial numbers to each product as required by regulations to prevent counterfeiting and improve distribution tracking.

Anti-Counterfeiting Marks

- Laser technology can create complex patterns or invisible markings, enhancing the product’s security.

Advantages Summary

- Regulatory Compliance: Meets strict pharmaceutical regulations for traceability and serialization.

- Cost-Effective and Eco-Friendly: No consumables required, reducing operational costs and chemical waste.

- High Efficiency: Supports high-speed production and real-time dynamic coding.

- Enhanced Security: Permanent, tamper-proof markings improve product safety.

Recommendations for Choosing a Laser Coding Machine

When selecting a laser coding machine for a pharmaceutical factory, consider the following factors:

- The type of packaging materials (e.g., glass, plastic, or paperboard).

- The complexity of the marking content (text, barcodes, QR codes).

- Production line speed and automation requirements.

- Compliance with regulatory requirements (e.g., serialization and anti-counterfeiting).

Laser coding machines meet the high standards of the pharmaceutical industry, ensuring efficient, accurate, and regulation-compliant marking, making them indispensable for modern pharmaceutical packaging.

laser marking machine for meta

laser marking machine for meta

laser marking machine price in

laser marking machine price in

HS code information of laser m

HS code information of laser m

20w fiber laser marking machin

20w fiber laser marking machin